Alloy Steel ASTM A182 F9 Flanges Manufacturers and Suppliers:

Alloy Steel A182 F9 flanges are commonly used in the petrochemical, oil and gas, and power generation industries. We are known for their high strength and corrosion resistance, which make ideal for use in harsh and corrosive environments.

We have a state-of-the-art manufacturing facility that is equipped with the latest technology and equipment to produce A182 F9 flanges to the highest standards. Our company’s team of highly skilled and experienced engineers and technicians ensures that all products meet the most stringent quality standards and customer specifications.

ISO Approved Alloy Steel A182 F9 Flanges Manufacturer In India, ASME SA182 F9 Blind Flange Dimensions & Weight Chart, Tolerances, Thickness, Cad Drawing, UNS K90941 Pipe Flange

ADCO Forge and Fittings is a reputable manufacturer of Alloy Steel A182 F9 flanges. We have been in the business of producing high-quality flanges for several years and built a reputation for delivering exceptional products to customers all around the world.

In addition to Alloy Steel A182 F9 flanges, also manufactures a wide range of other flanges, including carbon steel, stainless steel, and other alloy steel flanges. Our company’s product range includes weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and socket weld flanges.

We committed to providing its customers with the highest level of service and support. We have a dedicated customer service team that is available to answer any questions or concerns that customers may have. also offers customized solutions to meet the specific needs of its customers.

In summary, We are highly respected manufacturer of Alloy Steel A182 F9 flanges. Our company’s commitment to quality, innovation, and customer service made a trusted partner for businesses around the world.

We have the ready inventory of ASTM A182 Alloy Steel F9 Flanges in the different size ranges of 2 Inch, 3 Inch, 4 Inch, 6 Inch, 8 Inch, 9 Inch, 9/16 Emt ASTM A182 F9 Flanges .

Alloy Steel ASTM A182 F9 Flanges Standard Specifications

Standards

ASTM A182 / ASME SA182 Alloy Steel F5 Flanges, ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820

Din

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN2638, DIN2673

Class

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40.

JIS/UNI/BS

5K, 10K, 16K, 20K, 30K, 40K, 63K/ 6Bar 10Bar 16Bar 25Bar 40Bar/BS4504 , BS4504, BS1560, BS10

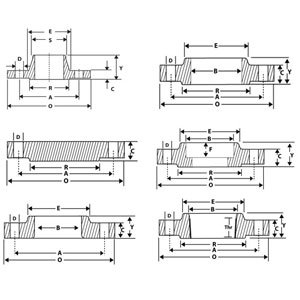

Dimensions

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size Range (inches)

From ½” (15 NB) to 48″ (1200NB)

Forms

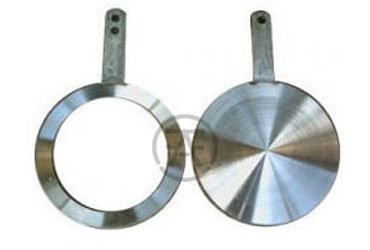

SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle

Connection Type

RTJ, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large, Tongue & Groove, Small Tongue & Groove

Face Type

Flat Face (FF), Raise Face (RF), Ring Joint (RJT)

ASTM A182 F9 Slip On Flange, Weld Neck Flange, Forged Flanges, WNR 1.7386 Blind Flange, RTJ Flange, Plate Flange, Chrome Moly A182 F9 SWRF Flange, WNRF Flange, Orifice Flange, Lap Joint Flange. Get best Price List.

ASTM A182 Alloy Steel F9 Flanges Types

If you are looking for ASTM A182 F9 Flanges types, weight chart, size chart, tolerance, and dimensions with drawings then kindly click the below-mentioned forms of pipe fittings as per your requirements to get the complete details. For the quick quote / price list click here.

Alloy Steel A182 F9 Flanges Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | Trade Name |

|---|---|---|---|

| Alloy Steel F9 | K90941 | 1.7386 | 9Cr-1Mo |

ASTM A182 F9 Flanges Chemical Composition

| Grade | C | si | mn | s | P | Cr | Mo |

|---|---|---|---|---|---|---|---|

| Alloy Steel F9 | 0.15 max | 0.3-0.6 | 0.5 - 1 | 0.03 | 0.03 | 8 - 10 | 0.9 - 1.1 |

Alloy Steel ASTM A182 F9 Weld Neck Flange Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

|---|---|---|---|

| Alloy Steel F9 | 380 | 585 | 20 |

ASTM A182 F9 Threaded Flange Weight Chart

| Flange Weights by Pressure Class and Size | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | 150 # | 300 # | 600 # | 900 # | 1500 # | 2500 # | ||||||||||||

| WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | |

| 1/2″ | 2 | 1 | 1 | 2 | 1 | 1 | 2 | 2 | 2 | SEE 1500 # WEIGHTS | 5 | 4 | 4 | 7 | 7 | 7 | ||

| 3/4″ | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | SEE 1500 # WEIGHTS | 6 | 5 | 6 | 8 | 8 | 8 | ||

| 1″ | 3 | 2 | 2 | 4 | 3 | 3 | 4 | 4 | 4 | SEE 1500 # WEIGHTS | 9 | 8 | 8 | 12 | 11 | 11 | ||

| 1 1/2″ | 4 | 3 | 3 | 7 | 6 | 6 | 8 | 7 | 8 | SEE 1500 # WEIGHTS | 13 | 12 | 13 | 25 | 22 | 23 | ||

| 2″ | 6 | 5 | 5 | 9 | 7 | 8 | 12 | 9 | 10 | SEE 1500 # WEIGHTS | 25 | 25 | 25 | 42 | 37 | 39 | ||

| 2 1/2″ | 8 | 7 | 7 | 12 | 10 | 12 | 18 | 13 | 15 | SEE 1500 # WEIGHTS | 36 | 36 | 35 | 52 | 55 | 56 | ||

| 3″ | 10 | 8 | 9 | 15 | 13 | 16 | 23 | 16 | 20 | 31 | 26 | 29 | 48 | 48 | 48 | 94 | 83 | 86 |

| 4″ | 15 | 13 | 17 | 25 | 22 | 27 | 42 | 37 | 41 | 53 | 53 | 54 | 73 | 73 | 73 | 145 | 125 | 130 |

| 5″ | 19 | 15 | 20 | 32 | 28 | 35 | 68 | 63 | 68 | 86 | 83 | 87 | 130 | 130 | 140 | 245 | 210 | 225 |

| 6″ | 24 | 19 | 26 | 42 | 39 | 50 | 81 | 80 | 86 | 110 | 110 | 115 | 165 | 165 | 160 | 380 | 325 | 345 |

| 8″ | 39 | 30 | 45 | 67 | 58 | 81 | 120 | 115 | 140 | 175 | 170 | 200 | 275 | 260 | 300 | 580 | 485 | 530 |

| 10″ | 52 | 43 | 70 | 91 | 81 | 124 | 190 | 170 | 230 | 260 | 245 | 290 | 455 | 435 | 510 | 1075 | 930 | 1025 |

| 12″ | 80 | 64 | 110 | 140 | 115 | 185 | 225 | 200 | 295 | 325 | 325 | 415 | 690 | 580 | 690 | 1525 | 1100 | 1300 |

| 14″ | 110 | 90 | 140 | 180 | 165 | 250 | 280 | 230 | 355 | 400 | 400 | 520 | 940 | NA | 975 | NA | NA | NA |

| 16″ | 140 | 98 | 180 | 250 | 190 | 295 | 390 | 330 | 495 | 495 | 425 | 600 | 1250 | NA | 1300 | NA | NA | NA |

| 18″ | 150 | 130 | 220 | 320 | 250 | 395 | 475 | 400 | 630 | 680 | 600 | 850 | 1625 | NA | 1750 | NA | NA | NA |

| 20″ | 180 | 165 | 285 | 400 | 315 | 505 | 590 | 510 | 810 | 830 | 730 | 1075 | 2050 | NA | 2225 | NA | NA | NA |

| 22″ | 225 | 185 | 355 | 465 | 370 | 640 | 720 | 590 | 1000 | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| 24″ | 260 | 220 | 430 | 580 | 475 | 790 | 830 | 730 | 1250 | 1500 | 1400 | 2025 | 3325 | NA | 3625 | NA | NA | NA |

ASTM A182 Alloy Steel F9 Flanges Dimenssional Tolerance

| WELDING NECK FLANGES | ||||

|---|---|---|---|---|

| 0 | Outside Diameter | When 0 is 24″or less | ±0.06″ | ±1.6 mm |

| When O is over 24” | ±0.12″ | ±3.2 mm | ||

| R | Diameter of Contact Face | 0.06” (1.6 mm) raised face | ±0.03″ | ±0.8 mm |

| 0.25″ (6.4 mm) raised face | ±0.02″ | ±0.5 mm | ||

| A | Diameter of Hub at Point of Welding | NPS 5 and smaller | +0.09″, -0.03″ | +2.4 mm, -0.8 mm |

| NPS 6 and larger | +0.16″, -0.03″ | +4.0 mm, -0.8 mm | ||

| B | Inside Diameter | NPS 10 and smaller | ±0.03″ | ±0.8 mm |

| NPS 12 to 18, inclusive | ±0.06″ | ±1.6 mm | ||

| NPS 20 and larger | +0.12″, -0.06” | +3.2 mm, -1.6 mm | ||

| X | Diameter of Hub at Base | When Hub Base is 24″ or less | ±0.06″ | ±1.6 mm |

| When Hub Base is over 24″ | ±0.12″ | ±3.2 mm | ||

| c | Thickness | NPS 18 and smaller | +0.12″, -0.00″ | +3.2 mm, -0.0 mm |

| NPS 20 and larger | +0.19″, -0.00″ | +4.8 mm, -0.0 mm | ||

| Drilling | Bolt Circle Diameter | ±0.06″ | ±1.6 mm | |

| Bolt Hole Spacing | ±0.03″ | ±0.8 mm | ||

| Eccentricity of Bolt Circle and Facing with Respect to Bore | NPS 21/2 and smaller | ±0.03″ | ±0.8 mm | |

| NPS 3 and larger | ±0.06″ | ±1.6 mm | ||

| Length Through Hub | NPS 10 and smaller | ±0.06″ | ±1.6 mm | |

| NPS 12 and larger | ±0.12″ | ±3.2 mm | ||

| SLIP-ON, LAP JOINT, SOCKET WELDING, THREADED AND BLIND FLANGES | ||||

| O | Outside Diameter | When O is 24″ or less When O is over 24″ |

±0.06″ ±0.12″ | ±1.6 mm ±3.2 mm |

| R | Diameter of Contact Face | 0.06″ (1.6 mm) raised face 0.25″ (6.4 mm) raised face | ±0.03″ ±0.02″ | ±0.8 mm ±0.5 mm |

| B | Inside Diameter at Face of Socket Welding Flanges

Inside Diameter of Slip-On, Lap Joint, and Socket Welding |

NPS 10 and smaller NPS 12 through 18, inclusive NPS 20 and larger |

±0.03″ ±0.06″ +0.12″, -0.06″ | ±0.8 mm ±1.6 mm +3.2 mm, -1.6 mm |

| NPS 10 and smaller NPS 12 and larger |

+0.03″, -0.00″ +0.06″, -0.00″ | +0.8 mm, -0.0 +1.6 mm, -0.0 mm |

||

| Q | Counterbore, Threaded Flanges | NPS 10 and smaller NPS 12 and larger |

+0.03″, -0.00″ +0.06″, -0.00″ | +0.8 mm, -0.0 + 1.6 mm, -0.0 mm |

| X | Diameter of Hub at Base | NPS 12 and smaller NPS 14 and larger |

+0.09″, -0.06″ ±0.12″ | +2.4 mm, -1.6 ±3.2 mm |

| c | Thickness | NPS 18 and smaller NPS 20 and larger |

+0.12″, -0.00″ +0.19″, -0.00″ | +3.2 mm, -0.0 +4.8 mm, -0.0 mm |

| Drilling | Bolt Circle Diameter Bolt Hole Spacing | ±0.06″ ±0.03″ | ±1.6 mm ±0.8 mm |

|

| Eccentricity of Bolt Circle and Facing with Respect to Bore | NPS 2V2 and smaller NPS 3 and larger |

±0.03″ ±0.06″ | ±0.8 mm ±1.6 mm |

|

| Overall Length Through Hub | NPS 18 and smaller NPS 20 and larger |

+0.12”, -0.03” +0.19”, -0.03” |

+3.2 mm, -0.8 mm +4.8 mm, -1.6 mm |

|

ASTM A182 F9 Forged Flange Applications

Oil and Gas

Nuclear Power & Defence

Petrochemical

LNG

Desalination

Mining & Minerals

Myanmar, Nepal, Thailand, Vietnam, Philippines, Malaysia, Indonesia,

Singapore, Taiwan, Tasmania, Sri Lanka, Bangladesh, Bhutan, Cambodia,

Australia, New Zealand, Afghanistan, Tajikistan, Kyrgyzstan, Kazakhstan,

Uzbekistan, Turkmenistan, Iran, United Arab Emirates(UAE), Saudi Arabia,

Oman, Yemen, Iraq, Azerbaijan, Turkiye, Syria, Lebanon, Israel, Kenya,

Egypt, South Sudan, Eritrea, Djibouti, Ethiopia, Libya, Rwanda, Mali,

Niger, Chad, Central Africa Republic, Nigeria, Cameroon, Somalia, DRC,

Uganda, Tanzania, Angola, Zambia, Madagascar, Malawi, Namibia, Benin,

Zimbabwe, Botswana, Lesotho, South Africa, Algeria, Tunisia, Morocco,

Eswatini, Liberia, Sierra Leone, The Gambia, Senegal, Mozambique, Togo,

Mauritania, Burkina Faso, Ghana, Equatorial Guinea, Jordan, Timor-Leste,

Palestine, Laos, Armenia, Georgia, Maldives, Cyprus, Kuwait, Qatar, Peru,

Bahrain, Brunei, Finland, France, Germany, Ireland, Iceland, UK, US,

Greece, Hungary, Italy, Norway, Poland, Slovakia, Sweden, Canada, Fiji,

Romania, Cuba, Panama, Brazil, Colombia, Chile, Argentina, Venezuela,

Naypyidaw, Kathmandu, Bangkok, Hanoi, Manila, Kuala Lumpur, Jakarta, Tunis,

Jurong East, Taipei City, Hobart, Sri Jayawardenepura Kotte, Dhaka, Thimphu,

Phnom Penh, Canberra, Wellington, Kabul, Dushanbe, Bishkek, Astana, Abuja,

Tashkent, Ashgabat, Tehran, Abu Dhabi, Riyadh, Muscat, Sana’a, Baghdad, Pretoria,

Baku, Ankara, Damascus, Beirut, Jerusalem, Nairobi, Cairo, Juba, Asmara, Rabat,

Djibouti city, Addis Ababa, Tripoli, Kigali, Bamako, Niamey, N’Djamena, Bangui,

Yaoundé, Mogadishu, Kinshasa, Kampala, Dodoma, Luanda, Lusaka, Antananarivo,

Lilongwe, Windhoek, Porto-Novo, Harare, Gaborone, Maseru, Cape Town, Bloemfontein,

Algiers, Mbabane, Lobamba, Monrovia, Freetown, Banjul, Dakar, Maputo, Lomé, Dili,

Nouakchott, Ouagadougou, Accra, Malabo, Amman, Vientiane, Yerevan, Tbilisi, Rome,

Malé, Nicosia, Kuwait City, Doha, Lima, Manama, Bandar Seri Begawan, Paris,

Helsinki, Berlin, Dublin, Reykjavík, London, Washington D.C., Athens, Budapest,

Oslo, Warsaw, Bratislava, Stockholm, Ottawa, Suva, Bucharest, Havana, Panama City,

Brasília, Bogotá, Santiago, Buenos Aires, Caracas, Mumabi, Chennai, Bengaluru,

Kolkata, Hyderabad, Pune, Ahmedabad, Jaipur, Surat, Visakhapatnam, Indore, New Delhi

Lucknow, Nagpur, Kochi, Kanpur, Guwahati, Coimbatore, Noida, Ghaziabad, Patna