ASME B16.47 Forged Flanges Manufacturers and Suppliers:

A Forged Flange is a type of flange that is produced through a process of forging, which involves shaping a piece of metal using compressive forces. This process results in a flange that is stronger and more durable than flanges made through other manufacturing methods.

Forged flanges are commonly used in high-pressure and high-temperature applications, such as oil and gas pipelines, chemical processing plants, and power generation facilities.

ISO Approved ANSI B16.5 Class 150, Class 300, Class 600, Class 900, Class 1500, Class 2500 Forged Flanges Manufacturer In India, BS10 Forged Flange, AWWA C207 Forged Flange, EN 1092-1 Forged Flange, Series A and Series B Forged Flange Dimensions Chart, Tolerances, Weight Chart, Thickness Chart, Cad Drawing Forged Flange

ADCO Forge and Fittings is a manufacturer of high-quality forged flanges. state-of-the-art manufacturing facility equipped with advanced forging equipment and experienced personnel, allowing to produce flanges in various sizes, shapes, and materials. We committed to providing superior products and exceptional customer service to meet the needs of our clients. We have a reputation for producing high-quality forged flanges that meet or exceed industry standards, making a trusted supplier to a wide range of industries, including oil and gas, chemical, and power generation.

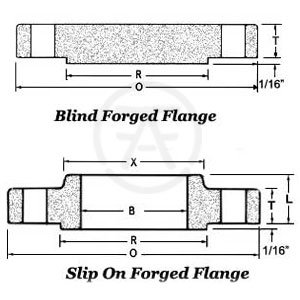

They are available in a variety of sizes, shapes, and materials, including carbon steel, stainless steel, and alloy steel. The most common types of forged flanges include slip-on flanges, weld neck flanges, socket weld flanges, and blind flanges.

Forged Flanges Standard Specifications

Standards

ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820

Form

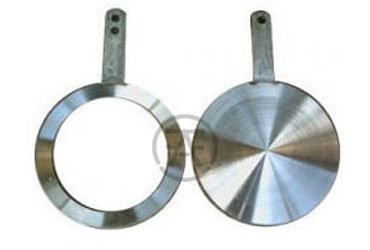

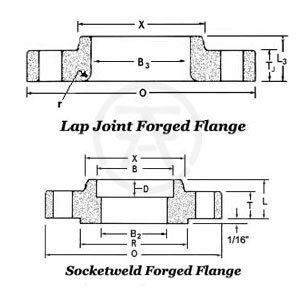

SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle

BS/JIS

BS4504 , BS4504, BS1560, BS10,5K, 10K, 16K, 20K, 30K, 40K, 63K

Face Type

Flat Face (FF), Raise Face (RF), Ring Joint (RJT)

Dimensions

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size Range (inches)

From ½” (15 NB) to 48″ (1200NB)

Class

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40.

Connection Type

RTJ, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large, Tongue & Groove, Small Tongue & Groove

Forged Flanges in Stainless Steel 304/304L, SS 316/316L, SS 904L, Alloy 20, Carbon Steel, Nickel 200, Monel, Inconel, Hastelloy C22, Duplex Steel 2205, Titanium, Copper Nickel, SMO 254, Aluminum, Galvanized, MS Forged Flange. Get best Price List.

ASME B16.47 Flanges Types

If you are looking for ASME B16.47 Pipe Flanges types, weight chart, size chart, tolerance, and dimensions with drawings then kindly click the below-mentioned forms of Flanges as per your requirements to get the complete details. For the quick quote / price list click here.

ASME B16.5 Forged Flanges Material Grades

| Stainless Steel Forged Flange: | ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F310MoLN, F316, F316H, F316L, F316N, F316LN, F316Ti, F317, F317L, F321, F321H, F347, F347H, F348, F348H, 904L |

|---|---|

| Carbon Steel Forged Flange: | ASTM A105 A53, A106, API 5L |

| Low Temperature Carbon Steel Forged Flange: | ASTM A350 LF1, LF2, LF3 |

| High Yield Carbon Steel Forged Flange: | ASTM A694 F42, F52, F60, F65 |

| Alloy Steel Forged Flange: | ASTM A182 F5, F9, F11, F22, F1, F5/F5a, F91 |

| Duplex & Super Duplex Forged Flange: | ASTM A182, ASME SA182 Duplex 2205 (UNS S31803 – UNS S32205), Super Duplex 2507 (UNS S32750 – UNS S32760) |

| Nickel Alloy Forged Flange: | ASTM / ASME SB B160 / B166 / B564 / B425/ B564 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C276 ), Cupro Nickel 90/10 ( C70600, 2.0872 ), 70/30 ( C71500, 2.0882) |

| Other Steel Forged Flange: | ASTM B381 Titanium Grade 2 ( R50400, 3.7035 ), Titanium Grade 5 ( N56400, 3.7165 ), ASTM B462 Alloy 20, ASTM A182 SMO 254/AL-6XN ( S31254, 1.4547 ), AISI 4130 ( G41300, 1.7218 ) |

ANSI B16.5 Forged Flanges Dimensions

ASME B16.5 Forged Flange - Dimensions

Dimensions of Class 150 Forged Flanges as per ANSI B16.5

| NPS | O | T | TJ | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | D | Thr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 3.50 | 0.38 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 0.88 | 0.62 | 0.90 | 0.84 | 0.56 | 1.81 | 0.62 | 0.12 | 0.38 | 0.62 |

| ¾ | 3.88 | 0.44 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 1.09 | 0.82 | 1.11 | 1.05 | 0.56 | 2.00 | 0.62 | 0.12 | 0.44 | 0.62 |

| 1 | 4.25 | 0.50 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 1.36 | 1.05 | 1.38 | 1.32 | 0.62 | 2.12 | 0.69 | 0.12 | 0.50 | 0.69 |

| 1¼ | 4.62 | 0.56 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 1.70 | 1.38 | 1.72 | 1.66 | 0.75 | 2.19 | 0.81 | 0.19 | 0.56 | 0.81 |

| 1½ | 5.00 | 0.62 | 0.69 | 2.88 | 2.56 | 4-0.62 | 3.88 | 1.95 | 1.61 | 1.97 | 1.90 | 0.81 | 2.38 | 0.88 | 0.25 | 0.62 | 0.88 |

| 2 | 6.00 | 0.69 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.44 | 2.07 | 2.46 | 2.38 | 0.94 | 2.44 | 1.00 | 0.31 | 0.69 | 1.00 |

| 2½ | 7.00 | 0.81 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.94 | 2.47 | 2.97 | 2.88 | 1.06 | 2.69 | 1.12 | 0.31 | 0.75 | 1.12 |

| 3 | 7.50 | 0.88 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 3.57 | 3.07 | 3.60 | 3.50 | 1.12 | 2.69 | 1.19 | 0.38 | 0.81 | 1.19 |

| 3½ | 8.50 | 0.88 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 4.07 | 3.55 | 4.10 | 4.00 | 1.19 | 2.75 | 1.25 | 0.38 | 0.88 | 1.25 |

| 4 | 9.00 | 0.88 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 4.57 | 4.03 | 4.60 | 4.50 | 1.25 | 2.94 | 1.31 | 0.44 | 0.94 | 1.31 |

| 5 | 10.00 | 0.88 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 5.66 | 5.05 | 5.69 | 5.56 | 1.38 | 3.44 | 1.44 | 0.44 | 0.94 | 1.44 |

| 6 | 11.00 | 0.94 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 6.72 | 6.07 | 6.75 | 6.63 | 1.50 | 3.44 | 1.56 | 0.50 | 1.06 | 1.56 |

| 8 | 13.50 | 1.06 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 8.72 | 7.98 | 8.75 | 8.63 | 1.69 | 3.94 | 1.75 | 0.50 | 1.25 | 1.75 |

| 10 | 16.00 | 1.12 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 10.88 | 10.02 | 10.92 | 10.75 | 1.88 | 3.94 | 1.94 | 0.50 | 1.31 | 1.94 |

| 12 | 19.00 | 1.19 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 12.88 | 12.00 | 12.92 | 12.75 | 2.12 | 4.44 | 2.19 | 0.50 | 1.56 | 2.19 |

| 14 | 21.00 | 1.31 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 14.14 | 13.25 | 14.18 | 14.00 | 2.19 | 4.94 | 3.12 | 0.50 | 1.63 | 2.25 |

| 16 | 23.50 | 1.38 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 16.16 | 15.25 | 16.19 | 16.00 | 2.44 | 4.94 | 3.44 | 0.50 | 1.75 | 2.50 |

| 18 | 25.00 | 1.50 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 18.18 | 17.25 | 18.20 | 18.00 | 2.62 | 5.44 | 3.81 | 0.50 | 1.94 | 2.69 |

| 20 | 27.50 | 1.62 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 20.20 | 19.25 | 20.25 | 20.00 | 2.81 | 5.62 | 4.06 | 0.50 | 2.13 | 2.88 |

| 22 | 29.50 | 1.75 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 22.22 | 21.25 | 22.25 | 22.00 | 3.07 | 5.82 | 4.25 | 0.50 | 2.38 | 3.13 |

| 24 | 32.00 | 1.81 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 24.25 | 23.25 | 24.25 | 24.00 | 3.19 | 5.94 | 4.38 | 0.50 | 2.50 | 3.25 |

Dimensions of Class 300 Forged Flanges as per ANSI B16.5

| NPS | O | T | TJ | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | D | Thr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 3.75 | 0.50 | 0.56 | 1.38 | 1.50 | 4-0.63 | 2.62 | 0.88 | 0.62 | 0.90 | 0.84 | 0.81 | 2.00 | 0.88 | 0.12 | 0.93 | 0.38 | 0.62 |

| ¾ | 4.62 | 0.56 | 0.62 | 1.69 | 1.88 | 4-0.75 | 3.25 | 1.09 | 0.82 | 1.11 | 1.05 | 0.94 | 2.19 | 1.00 | 0.12 | 1.14 | 0.44 | 0.62 |

| 1 | 4.88 | 0.62 | 0.69 | 2.00 | 2.12 | 4-0.75 | 3.50 | 1.36 | 1.05 | 1.38 | 1.32 | 1.00 | 2.38 | 1.06 | 0.12 | 1.41 | 0.50 | 0.69 |

| 1¼ | 5.25 | 0.69 | 0.75 | 2.50 | 2.50 | 4-0.75 | 3.88 | 1.70 | 1.38 | 1.72 | 1.66 | 1.00 | 2.50 | 1.06 | 0.19 | 1.75 | 0.56 | 0.81 |

| 1½ | 6.12 | 0.75 | 0.81 | 2.88 | 2.75 | 4-0.88 | 4.50 | 1.95 | 1.61 | 1.97 | 1.90 | 1.13 | 2.63 | 1.19 | 0.25 | 1.98 | 0.62 | 0.88 |

| 2 | 6.50 | 0.81 | 0.88 | 3.62 | 3.31 | 8-0.75 | 5.00 | 2.44 | 2.07 | 2.46 | 2.38 | 1.25 | 2.69 | 1.31 | 0.31 | 2.50 | 0.69 | 1.12 |

| 2½ | 7.50 | 0.94 | 1.00 | 4.12 | 3.94 | 8-0.88 | 5.88 | 2.94 | 2.47 | 2.97 | 2.88 | 1.44 | 2.94 | 1.50 | 0.31 | 3.00 | 0.75 | 1.25 |

| 3 | 8.25 | 1.06 | 1.12 | 5.00 | 4.62 | 8-0.88 | 6.62 | 3.57 | 3.07 | 3.60 | 3.50 | 1.63 | 3.06 | 1.69 | 0.38 | 3.63 | 0.81 | 1.25 |

| 3½ | 9.00 | 1.12 | 1.19 | 5.50 | 5.25 | 8-0.88 | 7.25 | 4.07 | 3.55 | 4.10 | 4.00 | 1.69 | 3.13 | 1.75 | 0.38 | 4.13 | …. | 1.44 |

| 4 | 10.00 | 1.19 | 1.25 | 6.19 | 5.75 | 8-0.88 | 7.88 | 4.57 | 4.03 | 4.60 | 4.50 | 1.82 | 3.32 | 1.88 | 0.44 | 4.63 | …. | 1.44 |

| 5 | 11.00 | 1.31 | 1.38 | 7.31 | 7.00 | 8-0.88 | 9.25 | 5.66 | 5.05 | 5.69 | 5.56 | 1.94 | 3.82 | 2.00 | 0.44 | 5.69 | …. | 1.69 |

| 6 | 12.50 | 1.38 | 1.44 | 8.50 | 8.12 | 12-0.88 | 10.62 | 6.72 | 6.07 | 6.75 | 6.63 | 2.00 | 3.82 | 2.06 | 0.50 | 6.75 | …. | 1.81 |

| 8 | 15.00 | 1.56 | 1.62 | 10.62 | 10.25 | 12-1.00 | 13.00 | 8.72 | 7.98 | 8.75 | 8.63 | 2.38 | 4.32 | 2.44 | 0.50 | 8.75 | …. | 2.00 |

| 10 | 17.50 | 1.81 | 1.88 | 12.75 | 12.62 | 16-1.12 | 15.25 | 10.88 | 10.02 | 10.92 | 10.75 | 2.56 | 4.56 | 3.75 | 0.50 | 10.88 | …. | 2.19 |

| 12 | 20.50 | 1.94 | 2.00 | 15.00 | 14.75 | 16-1.25 | 17.75 | 12.88 | 12.00 | 12.92 | 12.75 | 2.82 | 5.06 | 4.00 | 0.50 | 12.94 | …. | 2.38 |

| 14 | 23.00 | 2.06 | 2.12 | 16.25 | 16.75 | 20-1.25 | 20.25 | 14.14 | 13.25 | 14.18 | 14.00 | 2.94 | 5.56 | 4.38 | 0.50 | 14.19 | …. | 2.50 |

| 16 | 25.50 | 2.19 | 2.25 | 18.50 | 19.00 | 20-1.38 | 22.50 | 16.16 | 15.25 | 16.19 | 16.00 | 3.19 | 5.69 | 4.75 | 0.50 | 16.19 | …. | 2.69 |

| 18 | 28.00 | 2.31 | 2.38 | 21.00 | 21.00 | 24-1.38 | 24.75 | 18.18 | 17.25 | 18.20 | 18.00 | 3.44 | 6.19 | 5.12 | 0.50 | 18.19 | …. | 2.75 |

| 20 | 30.50 | 2.44 | 2.50 | 23.00 | 23.12 | 24-1.38 | 27.00 | 20.20 | 19.25 | 20.25 | 20.00 | 3.69 | 6.32 | 5.50 | 0.50 | 20.19 | …. | 2.88 |

| 22 | 33.00 | 2.57 | 2.63 | 25.25 | 25.25 | 24-1.63 | 29.25 | 22.22 | 21.25 | 22.25 | 22.00 | 3.93 | 6.43 | 5.75 | 0.50 | 22.19 | …. | 3.13 |

| 24 | 36.00 | 2.69 | 2.75 | 27.25 | 27.62 | 24-1.63 | 32.00 | 24.25 | 23.25 | 24.25 | 24.00 | 4.13 | 6.56 | 6.00 | 0.50 | 24.19 | …. | 3.25 |

Dimensions of Class 400 Forged Flanges as per ANSI B16.5

| NPS | O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | D | Thr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 3.75 | 0.56 | 1.38 | 1.5 | 4-0.63 | 2.62 | 0.88 |

|

0.9 | 0.84 | 0.88 | 2.06 | 0.88 | 0.12 | 0.93 | 0.38 | 0.62 |

| ¾ | 4.62 | 0.62 | 1.69 | 1.88 | 4-0.75 | 3.25 | 1.09 | 1.11 | 1.05 | 1 | 2.25 | 1 | 0.12 | 1.14 | 0.44 | 0.62 | |

| 1 | 4.88 | 0.69 | 2 | 2.12 | 4-.075 | 3.5 | 1.36 | 1.38 | 1.32 | 1.06 | 2.44 | 1.06 | 0.12 | 1.41 | 0.5 | 0.69 | |

| 1¼ | 5.25 | 0.81 | 2.5 | 2.5 | 4-0.75 | 3.88 | 1.7 | 1.72 | 1.66 | 1.12 | 2.62 | 1.12 | 0.19 | 1.75 | 0.56 | 0.81 | |

| 1½ | 6.12 | 0.88 | 2.88 | 2.75 | 4-0.88 | 4.5 | 1.95 | 1.97 | 1.9 | 1.25 | 2.75 | 1.25 | 0.25 | 1.99 | 0.62 | 0.88 | |

| 2 | 6.5 | 1 | 3.62 | 3.31 | 8-0.75 | 5 | 2.44 | 2.46 | 2.38 | 1.44 | 2.88 | 1.44 | 0.31 | 2.5 | 0.69 | 1.12 | |

| 2½ | 7.5 | 1.12 | 4.12 | 3.94 | 8-0.88 | 5.88 | 2.94 | 2.97 | 2.88 | 1.62 | 3.12 | 1.62 | 0.31 | 3 | 0.75 | 1.25 | |

| 3 | 8.25 | 1.25 | 5 | 4.62 | 8-0.88 | 6.62 | 3.57 | 3.6 | 3.5 | 1.81 | 3.25 | 1.81 | 0.38 | 3.63 | 0.81 | 1.38 | |

| 3½ | 9 | 1.38 | 5.5 | 5.25 | 8-1.00 | 7.25 | 4.07 | 4.1 | 4 | 1.94 | 3.38 | 1.94 | 0.38 | 4.13 | …. | 1.56 | |

| 4 | 10 | 1.38 | 6.19 | 5.75 | 8-1.00 | 7.88 | 4.57 | 4.6 | 4.5 | 2 | 3.5 | 2 | 0.44 | 4.63 | …. | 1.44 | |

| 5 | 11 | 1.5 | 7.31 | 7 | 8-1.00 | 9.25 | 5.66 | 5.69 | 5.56 | 2.12 | 4 | 2.12 | 0.44 | 5.69 | …. | 1.69 | |

| 6 | 12.5 | 1.62 | 8.5 | 8.12 | 12-1.00 | 10.62 | 6.72 | 6.75 | 6.63 | 2.25 | 4.06 | 2.25 | 0.5 | 6.75 | …. | 1.81 | |

| 8 | 15 | 1.88 | 10.62 | 10.25 | 12-1.12 | 13 | 8.72 | 8.75 | 8.63 | 2.69 | 4.62 | 2.69 | 0.5 | 8.75 | …. | 2 | |

| 10 | 17.5 | 2.12 | 12.75 | 12.62 | 16-1.25 | 15.25 | 10.88 | 10.92 | 10.75 | 2.88 | 4.88 | 4 | 0.5 | 10.88 | …. | 2.19 | |

| 12 | 20.5 | 2.25 | 15 | 14.75 | 16-1.38 | 17.75 | 12.88 | 12.92 | 12.75 | 3.12 | 5.38 | 4.25 | 0.5 | 12.94 | …. | 2.38 | |

| 14 | 23 | 2.38 | 16.25 | 16.75 | 20-1.38 | 20.25 | 14.14 | 14.18 | 14 | 3.31 | 5.88 | 4.62 | 0.5 | 14.19 | …. | 2.5 | |

| 16 | 25.5 | 2.5 | 18.5 | 19 | 20-1.50 | 22.5 | 16.16 | 16.19 | 16 | 3.69 | 6 | 5 | 0.5 | 16.19 | …. | 2.69 | |

| 18 | 28 | 2.62 | 21 | 21 | 24-1.50 | 24.75 | 18.18 | 18.2 | 18 | 3.88 | 6.5 | 5.38 | 0.5 | 18.19 | …. | 2.75 | |

| 20 | 30.5 | 2.75 | 23 | 23.12 | 24-1.62 | 27 | 20.2 | 20.25 | 20 | 4 | 6.62 | 5.75 | 0.5 | 20.19 | …. | 2.88 | |

| 22 | 33 | 2.88 | 25.25 | 25.25 | 24-1.75 | 29.25 | 22.22 | 22.25 | 22 | 4.25 | 6.75 | 6 | 0.5 | …. | …. | — | |

| 24 | 36 | 3 | 27.25 | 27.62 | 24-1.88 | 32 | 24.25 | 24.25 | 24 | 4.5 | 6.88 | 6.25 | 0.5 | 24.19 | …. | 3.25 |

Dimensions of Class 600 Forged Flanges as per ANSI B16.5

| Nom. Pipe Size | O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | D | Thr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 3.75 | 0.56 | 1.38 | 1.5 | 4-0.63 | 2.62 | 0.88 | 0.9 | 0.84 | 0.88 | 2.06 | 0.88 | 0.12 | 0.93 | 0.38 | 0.62 | |

| ¾ | 4.62 | 0.62 | 1.69 | 1.88 | 4-0.75 | 3.25 | 1.09 | 1.11 | 1.05 | 1 | 2.25 | 1 | 0.12 | 1.14 | 0.44 | 0.62 | |

| 1 | 4.88 | 0.69 | 2 | 2.12 | 4-0.75 | 3.5 | 1.36 | 1.38 | 1.32 | 1.06 | 2.44 | 1.06 | 0.12 | 1.41 | 0.5 | 0.69 | |

| 1¼ | 5.25 | 0.81 | 2.5 | 2.5 | 4-0.75 | 3.88 | 1.7 | 1.72 | 1.66 | 1.12 | 2.62 | 1.12 | 0.19 | 1.75 | 0.56 | 0.81 | |

| 1½ | 6.12 | 0.88 | 2.88 | 2.75 | 4-0.88 | 4.5 | 1.95 | 1.97 | 1.9 | 1.25 | 2.75 | 1.25 | 0.25 | 1.99 | 0.62 | 0.88 | |

| 2 | 6.5 | 1 | 3.62 | 3.31 | 8-0.75 | 5 | 2.44 | 2.46 | 2.38 | 1.44 | 2.88 | 1.44 | 0.31 | 2.5 | 0.69 | 1.12 | |

| 2½ | 7.5 | 1.12 | 4.12 | 3.94 | 8-0.88 | 5.88 | 2.94 | 2.97 | 2.88 | 1.62 | 3.12 | 1.62 | 0.31 | 3 | 0.75 | 1.25 | |

| 3 | 8.25 | 1.25 | 5 | 4.62 | 8-0.88 | 6.62 | 3.57 | 3.6 | 3.5 | 1.81 | 3.25 | 1.81 | 0.38 | 3.63 | 0.81 | 1.38 | |

| 3½ | 9 | 1.38 | 5.5 | 5.25 | 8-1.00 | 7.25 | 4.07 | 4.1 | 4 | 1.94 | 3.38 | 1.94 | 0.38 | 4.13 | …. | 1.56 | |

| 4 | 10.75 | 1.5 | 6.19 | 6 | 8-1.00 | 8.5 | 4.57 | 4.6 | 4.5 | 2.12 | 4 | 2.12 | 0.44 | 4.63 | …. | 1.62 | |

| 5 | 13 | 1.75 | 7.31 | 7.44 | 8-1.12 | 10.5 | 5.66 | 5.69 | 5.56 | 2.38 | 4.5 | 2.38 | 0.44 | 5.69 | …. | 1.88 | |

| 6 | 14 | 1.88 | 8.5 | 8.75 | 12-1.12 | 11.5 | 6.72 | 6.75 | 6.63 | 2.62 | 4.62 | 2.62 | 0.5 | 6.75 | …. | 2 | |

| 8 | 16.5 | 2.19 | 10.62 | 10.75 | 12-1.25 | 13.75 | 8.72 | 8.75 | 8.63 | 3 | 5.25 | 3 | 0.5 | 8.75 | …. | 2.25 | |

| 10 | 20 | 2.5 | 12.75 | 13.5 | 16-1.38 | 17 | 10.88 | 10.92 | 10.75 | 3.38 | 6 | 4.38 | 0.5 | 10.88 | …. | 2.56 | |

| 12 | 22 | 2.62 | 15 | 15.75 | 20-1.38 | 19.25 | 12.88 | 12.92 | 12.75 | 3.62 | 6.12 | 4.62 | 0.5 | 12.94 | …. | 2.75 | |

| 14 | 23.75 | 2.75 | 16.25 | 17 | 20-1.50 | 20.75 | 14.14 | 14.18 | 14 | 3.69 | 6.5 | 5 | 0.5 | 14.19 | …. | 2.88 | |

| 16 | 27 | 3 | 18.5 | 19.5 | 20-1.63 | 23.75 | 16.16 | 16.19 | 16 | 4.19 | 7 | 5.5 | 0.5 | 16.19 | …. | 3.06 | |

| 18 | 29.25 | 3.25 | 21 | 21.5 | 20-1.75 | 25.75 | 18.18 | 18.2 | 18 | 4.62 | 7.25 | 6 | 0.5 | 18.19 | …. | 3.12 | |

| 20 | 32 | 3.5 | 23 | 24 | 24-1.75 | 28.5 | 20.2 | 20.25 | 20 | 5 | 7.5 | 6.5 | 0.5 | 20.19 | …. | 3.25 | |

| 22 | 34.25 | 3.75 | 25.25 | 26.25 | 24-1.75 | 30.63 | 22.22 | 22.25 | 22 | 5.25 | 7.75 | 6.88 | 0.5 | …. | …. | — | |

| 24 | 37 | 4 | 27.25 | 28.25 | 24-2.00 | 33 | 24.25 | 24.25 | 24 | 5.5 | 8 | 7.25 | 0.5 | 24.19 | …. | 3.62 |

Dimensions of Class 900 Forged Flanges as per ANSI B16.5

| NPS | O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | Thr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sizes 1/2″ through 2 1/2″ are identical to class 1500. | ||||||||||||||||

| 3 | 9.5 | 1.5 | 5 | 5 | 8-1.00 | 7.5 | 3.57 | |

3.6 | 3.5 | 2.12 | 4 | 2.12 | 0.38 | 3.63 | 1.62 |

| 4 | 11.5 | 1.75 | 6.19 | 6.25 | 8-1.25 | 9.25 | 4.57 | 4.6 | 4.5 | 2.75 | 4.5 | 2.75 | 0.44 | 4.63 | 1.88 | |

| 5 | 13.75 | 2 | 7.31 | 7.5 | 8-1.38 | 11 | 5.66 | 5.69 | 5.56 | 3.12 | 5 | 3.12 | 0.44 | 5.69 | 2.12 | |

| 6 | 15 | 2.19 | 8.5 | 9.25 | 12-1.25 | 12.5 | 6.72 | 6.75 | 6.63 | 3.38 | 5.5 | 3.38 | 0.5 | 6.75 | 2.25 | |

| 8 | 18.5 | 2.5 | 10.63 | 11.75 | 12-1.50 | 15.5 | 8.72 | 8.75 | 8.63 | 4 | 6.38 | 4.5 | 0.5 | 8.75 | 2.5 | |

| 10 | 21.5 | 2.75 | 12.75 | 14.5 | 16-1.50 | 18.5 | 10.88 | 10.92 | 10.75 | 4.25 | 7.25 | 5 | 0.5 | 10.88 | 2.81 | |

| 12 | 24 | 3.12 | 15 | 16.5 | 20-1.50 | 21 | 12.88 | 12.92 | 12.75 | 4.63 | 7.88 | 5.62 | 0.5 | 12.94 | 3 | |

| 14 | 25.25 | 3.38 | 16.25 | 17.75 | 20-1.63 | 22 | 14.14 | 14.18 | 14 | 5.12 | 8.38 | 6.12 | 0.5 | 14.19 | 3.25 | |

| 16 | 27.75 | 3.5 | 18.5 | 20 | 20-1.75 | 24.25 | 16.16 | 16.19 | 16 | 5.25 | 8.5 | 6.5 | 0.5 | 16.19 | 3.38 | |

| 18 | 31 | 4 | 21 | 22.25 | 20-2.00 | 27 | 18.18 | 18.2 | 18 | 6 | 9 | 7.5 | 0.5 | 18.19 | 3.5 | |

| 20 | 33.75 | 4.25 | 23 | 24.5 | 20-2.13 | 29.5 | 20.2 | 20.25 | 20 | 6.25 | 9.75 | 8.25 | 0.5 | 20.19 | 3.62 | |

| 24 | 41 | 5.5 | 27.25 | 29.5 | 20-2.63 | 35.5 | 24.25 | 24.25 | 24 | 8 | 11.5 | 10.5 | 0.5 | 24.19 | 4 | |

Dimensions of Class 1500 Forged Flanges as per ANSI B16.5

| NPS | O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B | B2b | B3 | H | L | L2 | L3c | r | C | D | Thr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 4.75 | 0.88 | 1.38 | 1.5 | 4-0.88 | 3.25 | 0.88 |

|

0.9 | 0.84 | 1.25 | 2.38 | 1.25 | 0.12 | 0.93 | 0.38 | 0.88 |

| ¾ | 5.12 | 1 | 1.69 | 1.75 | 4-0.88 | 3.5 | 1.09 | 1.11 | 1.05 | 1.38 | 2.75 | 1.38 | 0.12 | 1.14 | 0.44 | 1 | |

| 1 | 5.88 | 1.12 | 2 | 2.06 | 4-1.00 | 4 | 1.36 | 1.38 | 1.32 | 1.62 | 2.88 | 1.62 | 0.12 | 1.41 | 0.5 | 1.12 | |

| 1¼ | 6.25 | 1.12 | 2.5 | 2.5 | 4-1.00 | 4.38 | 1.7 | 1.72 | 1.66 | 1.62 | 2.88 | 1.62 | 0.19 | 1.75 | 0.56 | 1.19 | |

| 1½ | 7 | 1.25 | 2.88 | 2.75 | 4-1.12 | 4.88 | 1.95 | 1.97 | 1.9 | 1.75 | 3.25 | 1.75 | 0.25 | 1.99 | 0.62 | 1.25 | |

| 2 | 8.5 | 1.5 | 3.63 | 4.12 | 8-1.00 | 6.5 | 2.44 | 2.46 | 2.38 | 2.25 | 4 | 2.25 | 0.31 | 2.5 | 0.69 | 1.5 | |

| 2½ | 9.62 | 1.62 | 4.13 | 4.88 | 8-1.12 | 7.5 | 2.94 | 2.97 | 2.88 | 2.5 | 4.12 | 2.5 | 0.31 | 3 | 0.75 | 1.88 | |

| 3 | 10.5 | 1.88 | 5 | 5.25 | 8-1.25 | 8 | …. | 3.6 | 3.5 | …. | 4.62 | 2.88 | 0.38 | …. | …. | …. | |

| 4 | 12.25 | 2.12 | 6.19 | 6.38 | 8-1.38 | 9.5 | …. | 4.6 | 4.5 | …. | 4.88 | 3.56 | 0.44 | …. | …. | …. | |

| 5 | 14.75 | 2.88 | 7.31 | 7.75 | 8-1.63 | 11.5 | …. | 5.69 | 5.56 | …. | 6.12 | 4.12 | 0.44 | …. | …. | …. | |

| 6 | 15.5 | 3.25 | 8.5 | 9 | 12-1.50 | 12.5 | …. | 6.75 | 6.63 | …. | 6.75 | 4.69 | 0.5 | …. | …. | …. | |

| 8 | 19 | 3.62 | 10.63 | 11.5 | 12-1.75 | 15.5 | …. | 8.75 | 8.63 | …. | 8.38 | 5.62 | 0.5 | …. | …. | …. | |

| 10 | 23 | 4.25 | 12.75 | 14.5 | 12-2.00 | 19 | …. | 10.92 | 10.75 | …. | 10 | 7 | 0.5 | …. | …. | …. | |

| 12 | 26.5 | 4.88 | 15 | 17.75 | 16-2.12 | 22.5 | …. | 12.92 | 12.75 | …. | 11.12 | 8.62 | 0.5 | …. | …. | …. | |

| 14 | 29.5 | 5.25 | 16.25 | 19.5 | 16-2.38 | 25 | …. | 14.18 | 14 | …. | 11.75 | 9.5 | 0.5 | …. | …. | …. | |

| 16 | 32.5 | 5.75 | 18.5 | 21.75 | 16-2.63 | 27.75 | …. | 16.19 | 16 | …. | 12.25 | 10.25 | 0.5 | …. | …. | …. | |

| 18 | 36 | 6.38 | 21 | 23.5 | 16-2.88 | 30.5 | …. | 18.2 | 18 | …. | 12.88 | 10.88 | 0.5 | …. | …. | …. | |

| 20 | 38.75 | 7 | 23 | 25.25 | 16-3.12 | 32.75 | …. | 20.25 | 20 | …. | 14 | 11.5 | 0.5 | …. | …. | …. | |

| 24 | 46 | 8 | 27.25 | 30 | 16-3.63 | 39 | …. | 24.25 | 24 | …. | 16 | 13 | 0.5 | …. | …. | …. |

Dimensions of Class 2500 Forged Flanges as per ANSI B16.5

| NPS | O | T | R | X | #/Dia of Holesa | Bolt Circle Dia | B2b | B3 | H | L | L2 | L3 | r | C | Thr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 5.25 | 1.19 | 1.38 | 1.69 | 4-0.88 | 3.5 | 0.9 | 0.84 | 1.56 | 2.88 | 1.56 | 0.12 | 0.93 | 1.12 | |

| ¾ | 5.5 | 1.25 | 1.69 | 2 | 4-0.88 | 3.75 | 1.11 | 1.05 | 1.69 | 3.12 | 1.69 | 0.12 | 1.14 | 1.25 | |

| 1 | 6.25 | 1.38 | 2 | 2.25 | 4-1.00 | 4.25 | 1.38 | 1.32 | 1.88 | 3.5 | 1.88 | 0.12 | 1.41 | 1.38 | |

| 1¼ | 7.25 | 1.5 | 2.5 | 2.88 | 4-1.12 | 5.13 | 1.72 | 1.66 | 2.06 | 3.75 | 2.06 | 0.19 | 1.75 | 1.5 | |

| 1½ | 8 | 1.75 | 2.88 | 3.12 | 4-1.25 | 5.75 | 1.97 | 1.9 | 2.38 | 4.38 | 2.38 | 0.25 | 1.99 | 1.75 | |

| 2 | 9.25 | 2 | 3.63 | 3.75 | 8-1.12 | 6.75 | 2.46 | 2.38 | 2.75 | 5 | 2.75 | 0.31 | 2.5 | 2 | |

| 2½ | 10.5 | 2.25 | 4.13 | 4.5 | 8-1.25 | 7.75 | 2.97 | 2.88 | 3.12 | 5.62 | 3.12 | 0.31 | 3 | 2.25 | |

| 3 | 12 | 2.62 | 5 | 5.25 | 8-1.38 | 9 | 3.6 | 3.5 | …. | 6.62 | 3.62 | 0.38 | …. | …. | |

| 4 | 14 | 3 | 6.19 | 6.5 | 8-1.63 | 10.75 | 4.6 | 4.5 | …. | 7.5 | 4.25 | 0.44 | …. | …. | |

| 5 | 16.5 | 3.62 | 7.31 | 8 | 8-1.88 | 12.75 | 5.69 | 5.56 | …. | 9 | 5.12 | 0.44 | …. | …. | |

| 6 | 19 | 4.25 | 8.5 | 9.25 | 8-2.12 | 14.5 | 6.75 | 6.63 | …. | 10.75 | 6 | 0.5 | …. | …. | |

| 8 | 21.75 | 5 | 10.63 | 12 | 12-2.12 | 17.25 | 8.75 | 8.63 | …. | 12.5 | 7 | 0.5 | …. | …. | |

| 10 | 26.5 | 6.5 | 12.75 | 14.75 | 12-2.63 | 21.25 | 10.92 | 10.75 | …. | 16.5 | 9 | 0.5 | …. | …. | |

| 12 | 30 | 7.25 | 15 | 17.38 | 12-2.88 | 24.38 | 12.92 | 12.75 | …. | 18.25 | 10 | 0.5 | …. | …. |

Weight Chart of Class 150 Forged Flanges as per ANSI B16.5 – ( NPS ½” – 24” )

| 150 lb | ½ | 1 | 1 | 2 | 1 | 2 | 2 |

|---|---|---|---|---|---|---|---|

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 | |

| Class | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

Weight Chart of Class 300 Forged Flanges as per ANSI B16.5 – ( NPS ½” – 24” )

| Class | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

|---|---|---|---|---|---|---|---|

| 300 lb | ½ | 2 | 2 | 3 | 2 | 2 | 2 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1 | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4 | 4.5 | 6 | 5 | |

| 1½ | 6.5 | 6.5 | 6 | 6.5 | 7 | 7 | |

| 2 | 7 | 7 | 7 | 7 | 8 | 9 | |

| 2½ | 10 | 10 | 10 | 10 | 12 | 12 | |

| 3 | 13 | 14 | 13 | 14.5 | 16 | 18 | |

| 3½ | 17 | 17 | 17 | 17 | 21 | 20 | |

| 4 | 23.5 | 24 | 22 | 24 | 28 | 26.5 | |

| 5 | 29 | 31 | 28 | 28 | 37 | 36 | |

| 6 | 39 | 39 | 39 | 39 | 50 | 45 | |

| 8 | 58 | 58 | 58 | 58 | 81 | 69 | |

| 10 | 81 | 81 | 81 | 91 | 124 | 100 | |

| 12 | 115 | 115 | 115 | 140 | 185 | 142 | |

| 14 | 165 | 165 | 165 | 190 | 250 | 206 | |

| 16 | 210 | 220 | 190 | 234 | 315 | 250 | |

| 18 | 253 | 280 | 250 | 305 | 414 | 320 | |

| 20 | 315 | 325 | 315 | 375 | 515 | 400 | |

| 22 | 370 | 370 | 370 | 435 | 640 | 465 | |

| 24 | 490 | 490 | 475 | 550 | 800 | 580 |

Weight Chart of Class 400 Forged Flanges as per ANSI B16.5 – ( NPS ½” – 24” )

| Class | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

|---|---|---|---|---|---|---|---|

| 400 lb | ½ | 2 | 2 | 2 | 2 | 2 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3.5 | |

| 1 | 3.5 | 3.5 | 3.5 | 3.5 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4.5 | 4.5 | 6 | 4.5 | |

| 1½ | 6.5 | 6.5 | 6.5 | 6.5 | 8 | 8 | |

| 2 | 8 | 8 | 8 | 8 | 10 | 10 | |

| 2½ | 12 | 12 | 12 | 11 | 15 | 14 | |

| 3 | 15 | 15 | 15 | 14 | 20 | 18 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 26 | 26 | 26 | 25 | 33 | 35 | |

| 5 | 31 | 31 | 31 | 29 | 44 | 43 | |

| 6 | 44 | 44 | 44 | 42 | 61 | 57 | |

| 8 | 67 | 67 | 67 | 64 | 100 | 89 | |

| 10 | 91 | 91 | 91 | 110 | 155 | 125 | |

| 12 | 130 | 130 | 130 | 152 | 226 | 175 | |

| 14 | 191 | 191 | 191 | 210 | 310 | 233 | |

| 16 | 253 | 253 | 253 | 280 | 398 | 295 | |

| 18 | 310 | 310 | 310 | 345 | 502 | 360 | |

| 20 | 378 | 378 | 378 | 420 | 621 | 445 | |

| 22 | 405 | 405 | 405 | 455 | 720 | 505 | |

| 24 | 539 | 539 | 539 | 615 | 936 | 640 |

Weight Chart of Class 600 Forged Flanges as per ANSI B16.5 – ( NPS ½” – 24” )

| Class | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

|---|---|---|---|---|---|---|---|

| 600 lb | ½ | 2 | 2 | 2 | 2 | 3 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1 | 4 | 4 | 4 | 4 | 4 | 4 | |

| 1¼ | 5 | 5 | 5 | 5 | 6 | 6 | |

| 1½ | 7 | 7 | 7 | 7 | 8 | 8 | |

| 2 | 9 | 9 | 9 | 9 | 10 | 12 | |

| 2½ | 13 | 13 | 13 | 12 | 15 | 18 | |

| 3 | 16 | 16 | 16 | 15 | 20 | 23 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 37 | 37 | 37 | 36 | 41 | 42 | |

| 5 | 63 | 63 | 63 | 63 | 68 | 68 | |

| 6 | 80 | 80 | 80 | 78 | 86 | 81 | |

| 8 | 115 | 115 | 115 | 112 | 140 | 120 | |

| 10 | 177 | 177 | 177 | 195 | 231 | 190 | |

| 12 | 215 | 215 | 215 | 240 | 295 | 226 | |

| 14 | 259 | 259 | 259 | 290 | 378 | 347 | |

| 16 | 366 | 366 | 366 | 400 | 527 | 481 | |

| 18 | 476 | 476 | 476 | 469 | 665 | 555 | |

| 20 | 612 | 612 | 612 | 604 | 855 | 690 | |

| 22 | 590 | 590 | 590 | 670 | 1000 | 720 | |

| 24 | 876 | 876 | 876 | 866 | 1250 | 977 |

Weight Chart of Class 900 Forged Flanges as per ANSI B16.5 – ( NPS ½” – 24” )

| Class | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

|---|---|---|---|---|---|---|---|

| 900 lb | ½ | 6 | 6 | 6 | 6 | 4 | 7 |

| ¾ | 6 | 6 | 6 | 6 | 6 | 7 | |

| 1 | 7.5 | 7.5 | 7.5 | 7.5 | 9 | 8.5 | |

| 1¼ | 10 | 10 | 10 | 10 | 10 | 10 | |

| 1½ | 14 | 14 | 14 | 14 | 14 | 14 | |

| 2 | 22 | 22 | 22 | 21 | 25 | 24 | |

| 2½ | 31 | 31 | 31 | 25 | 32 | 31 | |

| 3 | 36 | 36 | 36 | 29 | 35 | 36 | |

| 4 | 53 | 53 | 53 | 51 | 54 | 53 | |

| 5 | 83 | 83 | 83 | 81 | 87 | 86 | |

| 6 | 110 | 110 | 110 | 105 | 115 | 110 | |

| 8 | 172 | 172 | 172 | 190 | 200 | 187 | |

| 10 | 245 | 245 | 245 | 277 | 290 | 268 | |

| 12 | 326 | 326 | 326 | 371 | 415 | 372 | |

| 14 | 400 | 400 | 400 | 415 | 520 | 562 | |

| 16 | 459 | 459 | 459 | 488 | 619 | 685 | |

| 18 | 647 | 647 | 647 | 670 | 880 | 924 | |

| 20 | 792 | 792 | 792 | 868 | 1107 | 1164 | |

| 24 | 1480 | 1480 | 1480 | 1659 | 2099 | 2107 |

Weight Chart of Class 1500 Forged Flanges as per ANSI B16.5 – ( NPS ½” – 24” )

| Class | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck | 1500 lb | ½ | 6 | 6 | 6 | 6 | 4 | 7 |

|---|---|---|---|---|---|---|---|

| ¾ | 6 | 6 | 6 | 6 | 6 | 7 | |

| 1 | 8 | 8 | 8 | 8 | 9 | 9 | |

| 1¼ | 10 | 10 | 10 | 10 | 10 | 10 | |

| 1½ | 14 | 14 | 14 | 14 | 14 | 14 | |

| 2 | 25 | 25 | 25 | 25 | 25 | 25 | |

| 2½ | 36 | 36 | 36 | 35 | 35 | 36 | |

| 3 | 48 | 48 | 48 | 47 | 48 | 48 | |

| 4 | 73 | 73 | 73 | 75 | 73 | 73 | |

| 5 | 132 | 132 | 132 | 140 | 140 | 132 | |

| 6 | 165 | 165 | 165 | 170 | 160 | 165 | |

| 8 | 260 | 260 | 260 | 286 | 302 | 275 | |

| 10 | 436 | 436 | 436 | 485 | 510 | 455 | |

| 12 | 667 | 667 | 667 | 749 | 775 | 690 | |

| 14 | 940 | 940 | 940 | 890 | 975 | 940 | |

| 16 | 1250 | 1250 | 1250 | 1250 | 1300 | 1250 | |

| 18 | 1625 | 1625 | 1625 | 1475 | 1750 | 1625 | |

| 20 | 2050 | 2050 | 2050 | 1775 | 2225 | 2050 | |

| 24 | 2825 | 2825 | 2825 | 2825 | 3625 | 3325 |

Forged Flanges ASME B16.47 Tolerance

| WELDING NECK FLANGES | ||||

|---|---|---|---|---|

| 0 | Outside Diameter | When 0 is 24″or less | ±0.06″ | ±1.6 mm |

| When O is over 24” | ±0.12″ | ±3.2 mm | ||

| R | Diameter of Contact Face | 0.06” (1.6 mm) raised face | ±0.03″ | ±0.8 mm |

| 0.25″ (6.4 mm) raised face | ±0.02″ | ±0.5 mm | ||

| A | Diameter of Hub at Point of Welding | NPS 5 and smaller | +0.09″, -0.03″ | +2.4 mm, -0.8 mm |

| NPS 6 and larger | +0.16″, -0.03″ | +4.0 mm, -0.8 mm | ||

| B | Inside Diameter | NPS 10 and smaller | ±0.03″ | ±0.8 mm |

| NPS 12 to 18, inclusive | ±0.06″ | ±1.6 mm | ||

| NPS 20 and larger | +0.12″, -0.06” | +3.2 mm, -1.6 mm | ||

| X | Diameter of Hub at Base | When Hub Base is 24″ or less | ±0.06″ | ±1.6 mm |

| When Hub Base is over 24″ | ±0.12″ | ±3.2 mm | ||

| c | Thickness | NPS 18 and smaller | +0.12″, -0.00″ | +3.2 mm, -0.0 mm |

| NPS 20 and larger | +0.19″, -0.00″ | +4.8 mm, -0.0 mm | ||

| Drilling | Bolt Circle Diameter | ±0.06″ | ±1.6 mm | |

| Bolt Hole Spacing | ±0.03″ | ±0.8 mm | ||

| Eccentricity of Bolt Circle and Facing with Respect to Bore | NPS 21/2 and smaller | ±0.03″ | ±0.8 mm | |

| NPS 3 and larger | ±0.06″ | ±1.6 mm | ||

| Length Through Hub | NPS 10 and smaller | ±0.06″ | ±1.6 mm | |

| NPS 12 and larger | ±0.12″ | ±3.2 mm | ||

| SLIP-ON, LAP JOINT, SOCKET WELDING, THREADED AND BLIND FLANGES | ||||

| O | Outside Diameter | When O is 24″ or less When O is over 24″ |

±0.06″ ±0.12″ | ±1.6 mm ±3.2 mm |

| R | Diameter of Contact Face | 0.06″ (1.6 mm) raised face 0.25″ (6.4 mm) raised face | ±0.03″ ±0.02″ | ±0.8 mm ±0.5 mm |

| B | Inside Diameter at Face of Socket Welding Flanges

Inside Diameter of Slip-On, Lap Joint, and Socket Welding |

NPS 10 and smaller NPS 12 through 18, inclusive NPS 20 and larger |

±0.03″ ±0.06″ +0.12″, -0.06″ | ±0.8 mm ±1.6 mm +3.2 mm, -1.6 mm |

| NPS 10 and smaller NPS 12 and larger |

+0.03″, -0.00″ +0.06″, -0.00″ | +0.8 mm, -0.0 +1.6 mm, -0.0 mm |

||

| Q | Counterbore, Threaded Flanges | NPS 10 and smaller NPS 12 and larger |

+0.03″, -0.00″ +0.06″, -0.00″ | +0.8 mm, -0.0 + 1.6 mm, -0.0 mm |

| X | Diameter of Hub at Base | NPS 12 and smaller NPS 14 and larger |

+0.09″, -0.06″ ±0.12″ | +2.4 mm, -1.6 ±3.2 mm |

| c | Thickness | NPS 18 and smaller NPS 20 and larger |

+0.12″, -0.00″ +0.19″, -0.00″ | +3.2 mm, -0.0 +4.8 mm, -0.0 mm |

| Drilling | Bolt Circle Diameter Bolt Hole Spacing | ±0.06″ ±0.03″ | ±1.6 mm ±0.8 mm |

|

| Eccentricity of Bolt Circle and Facing with Respect to Bore | NPS 2V2 and smaller NPS 3 and larger |

±0.03″ ±0.06″ | ±0.8 mm ±1.6 mm |

|

| Overall Length Through Hub | NPS 18 and smaller NPS 20 and larger |

+0.12”, -0.03” +0.19”, -0.03” |

+3.2 mm, -0.8 mm +4.8 mm, -1.6 mm |

|

MSS SP-44 Forged Flanges Applications

Oil and Gas

Nuclear Power & Defence

Petrochemical

LNG

Desalination

Mining & Minerals

Myanmar, Nepal, Thailand, Vietnam, Philippines, Malaysia, Indonesia,

Singapore, Taiwan, Tasmania, Sri Lanka, Bangladesh, Bhutan, Cambodia,

Australia, New Zealand, Afghanistan, Tajikistan, Kyrgyzstan, Kazakhstan,

Uzbekistan, Turkmenistan, Iran, United Arab Emirates(UAE), Saudi Arabia,

Oman, Yemen, Iraq, Azerbaijan, Turkiye, Syria, Lebanon, Israel, Kenya,

Egypt, South Sudan, Eritrea, Djibouti, Ethiopia, Libya, Rwanda, Mali,

Niger, Chad, Central Africa Republic, Nigeria, Cameroon, Somalia, DRC,

Uganda, Tanzania, Angola, Zambia, Madagascar, Malawi, Namibia, Benin,

Zimbabwe, Botswana, Lesotho, South Africa, Algeria, Tunisia, Morocco,

Eswatini, Liberia, Sierra Leone, The Gambia, Senegal, Mozambique, Togo,

Mauritania, Burkina Faso, Ghana, Equatorial Guinea, Jordan, Timor-Leste,

Palestine, Laos, Armenia, Georgia, Maldives, Cyprus, Kuwait, Qatar, Peru,

Bahrain, Brunei, Finland, France, Germany, Ireland, Iceland, UK, US,

Greece, Hungary, Italy, Norway, Poland, Slovakia, Sweden, Canada, Fiji,

Romania, Cuba, Panama, Brazil, Colombia, Chile, Argentina, Venezuela,

Naypyidaw, Kathmandu, Bangkok, Hanoi, Manila, Kuala Lumpur, Jakarta, Tunis,

Jurong East, Taipei City, Hobart, Sri Jayawardenepura Kotte, Dhaka, Thimphu,

Phnom Penh, Canberra, Wellington, Kabul, Dushanbe, Bishkek, Astana, Abuja,

Tashkent, Ashgabat, Tehran, Abu Dhabi, Riyadh, Muscat, Sana’a, Baghdad, Pretoria,

Baku, Ankara, Damascus, Beirut, Jerusalem, Nairobi, Cairo, Juba, Asmara, Rabat,

Djibouti city, Addis Ababa, Tripoli, Kigali, Bamako, Niamey, N’Djamena, Bangui,

Yaoundé, Mogadishu, Kinshasa, Kampala, Dodoma, Luanda, Lusaka, Antananarivo,

Lilongwe, Windhoek, Porto-Novo, Harare, Gaborone, Maseru, Cape Town, Bloemfontein,

Algiers, Mbabane, Lobamba, Monrovia, Freetown, Banjul, Dakar, Maputo, Lomé, Dili,

Nouakchott, Ouagadougou, Accra, Malabo, Amman, Vientiane, Yerevan, Tbilisi, Rome,

Malé, Nicosia, Kuwait City, Doha, Lima, Manama, Bandar Seri Begawan, Paris,

Helsinki, Berlin, Dublin, Reykjavík, London, Washington D.C., Athens, Budapest,

Oslo, Warsaw, Bratislava, Stockholm, Ottawa, Suva, Bucharest, Havana, Panama City,

Brasília, Bogotá, Santiago, Buenos Aires, Caracas, Mumabi, Chennai, Bengaluru,

Kolkata, Hyderabad, Pune, Ahmedabad, Jaipur, Surat, Visakhapatnam, Indore, New Delhi

Lucknow, Nagpur, Kochi, Kanpur, Guwahati, Coimbatore, Noida, Ghaziabad, Patna