Nickel Alloy 90 Degree Elbow Manufacturers and Suppliers:

High nickel alloys are commonly used in applications where high temperature, corrosion resistance, and/or high strength are required. High nickel alloys elbows are pipe fittings that are made from these materials and are commonly used in piping systems that transport fluids or gases.

High nickel alloys elbows can be manufactured in various shapes and sizes, including 90-degree elbows, 45-degree elbows, and custom bends. High nickel alloys elbows can be welded, threaded, or flanged to connect to other piping components.

ISO Approved Hastelloy 45 Degree Elbow Manufacturer In India, Inconel Seamless Elbow, Monel Short Radius 90 Degree Elbow, Copper Nickel seamless elbow, Inconel 600 45° Long Radius Elbow, Hastelloy C22 180° Long Radius Elbow Dimensions Chart, Tolerances, Weight Chart

High nickel alloys elbows are ideal for use in harsh environments, such as in chemical processing, power generation, and oil and gas industries, where they can withstand high temperatures, corrosion, and erosion. These materials can also be used in cryogenic applications due to their low thermal expansion coefficient.

The most commonly used high nickel alloys for elbows are Inconel, Monel, Hastelloy, and Nickel 200. These materials have high strength, excellent corrosion resistance, and good thermal stability, making them ideal for use in demanding applications.

When selecting a high nickel alloys elbow, it is important to consider factors such as temperature, pressure, fluid composition, and operating conditions. It is also important to ensure that the elbow meets industry standards and specifications to ensure its safe and reliable performance.

We have the ready inventory of High Nickel Alloys Elbow in the different size ranges of 2 Inch, 3 Inch, 3.5 Inch, 5 Inch, 6 Inch, 7 Inch, 8 Inch, 9 Inch SR and LR Elbows.

High Nickel Alloys Elbow Standard Specifications

Standards

ASTM B366/ ASME SB366, ANSI / ASME B16.9, MSS SP-43, API 590-605

Thickness

SCH10, SCH 20, SCH30, STD SCH40, SCH80, SCH60, XS, SCH100, SCH 120, SCH140, SCH 160, XXS available with NACE MR 01-75

Types

Welded | Seamless | Fabricated

Dimensions

ASME/ ANSI B16.9 | ASME B16.28 | MSS-SP-43 | BS1560 | BS4504 | BS10

Size Range (inches)

Seamless Elbow ( 1/2″~24″)

ERW/Fabricated/Welded Elbow (1/2″~48″)

Forms

90 Deg Elbow, 45 Deg Elbow, 180 Deg Elbow

ASTM B366 Elbows, Inconel 625 45 Degree Elbow, 1D Elbow, Hastelloy C276 1.5D Elbow, Incoloy 800 5D Elbow, Monel 400 3D Elbow, Incoloy 800 90 Degree Elbow, Incoloy 825 Seamless Elbow, Alloy 20 SR Elbow, SMO 254 Welded Elbows, Titanium Alloy 45 Degree Elbow. Get best Price List.

High Nickel Alloy Elbow Types

If you are looking for ASTM B366 Nickel Alloy Elbow Pipe Fittings types, weight chart, size chart, tolerance, and dimensions with drawings then kindly click the below-mentioned forms of pipe fittings as per your requirements to get the complete details. For the quick quote / price list click here.

Nickel Alloy Elbow Dimensions and Weights Chart

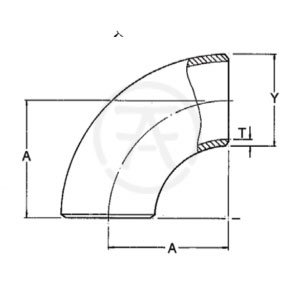

Nickel Alloy 90 Degree Elbow - Short and Long Radius - Dimensions and Weights Chart

Dimensions and weights of Inconel 90 degree short and long radius elbows (NPS 1/2 to 24, schedule STD/XS)

| Pipe Elbow Nominal Size | Pipe ElbowOutside Diameter Y |

WallThicknessT (Pipe Elbow Schedule) |

90 Deg. Elbow LR Centre to Face A |

90 Deg. Elbow LR Weight |

90 Deg. Elbow SR Centre to Face A |

90 Deg. Elbow SR Weight |

||

|---|---|---|---|---|---|---|---|---|

| mm | in | mm | mm | Schedule | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 914.0 | 269.0 | 610.0 | 179.0 | |||

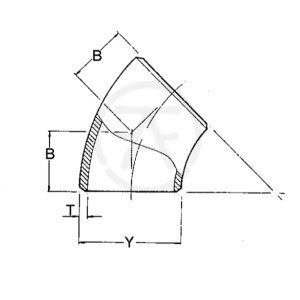

Hastelloy 45 Degree Elbow - Short and Long Radius - Dimensions and Weights Chart

Dimensions and weights of Hastelloy C276 Buttweld 45 degree short and long radius elbows (NPS 1/2 to 24, schedule STD/XS)

| Pipe Elbow Nominal Size | Pipe ElbowOutside Diameter Y |

WallThicknessT (Pipe Elbow Schedule) |

45 Deg. Elbow LR Centre toFace B | 45 Deg. Elbow LR Weight |

||

|---|---|---|---|---|---|---|

| mm | in | mm | mm | Schedule | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 |

| 3.73 | X.S | 15.9 | 0.05 | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 |

| 3.91 | X.S | 11.1 | 0.05 | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 |

| 4.55 | X.S | 22.2 | 0.11 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 |

| 4.85 | X.S | 25.4 | 0.2 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 |

| 5.08 | X.S | 28.6 | 0.25 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 |

| 5.54 | X.S | 34.9 | 0.5 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 |

| 7.01 | X.S | 44.4 | 0.91 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 |

| 7.62 | X.S | 50.8 | 1.45 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 |

| 8.56 | X.S | 63.5 | 2.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 |

| 9.5 | X.S | 79.4 | 5.0 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 |

| 10.97 | X.S | 95.2 | 7.7 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 |

| 12.7 | X.S | 127.0 | 15.5 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 |

| 12.7 | X.S | 159.0 | 24.4 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 |

| 12.7 | X.S | 190.0 | 35.0 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 |

| 12.7 | X.S | 222.0 | 45.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 |

| 12.7 | X.S | 254.0 | 59.0 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 |

| 12.7 | X.S | 286.0 | 75.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 |

| 12.7 | X.S | 318.0 | 112.5 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 |

| 12.7 | X.S | 381.0 | 134.5 | |||

Nickel Alloy 180 Degree Elbow - Short and Long Radius - Dimensions

Dimensions of Nickel Alloy 200 180 degree short and long radius elbows (NPS 1/2 to 24, schedule STD/XS)

| Pipe Elbow Nominal Size | Pipe Elbow Outside. D |

180° Deg. Elbow LR | 180° Deg. Elbow SR | ||

|---|---|---|---|---|---|

| Center to Center O |

Back to Face K |

Center to Center O |

Back to Face K |

||

| 1/2 | 21.3 | 76 | 48 | ||

| 3/4 | 26.7 | 76 | 51 | ||

| 1 | 33.4 | 76 | 56 | 51 | 41 |

| 1.1/4 | 42.2 | 95 | 70 | 64 | 52 |

| 1.1/2 | 48.3 | 114 | 83 | 76 | 62 |

| 2 | 60.3 | 152 | 106 | 102 | 81 |

| 2.1/2 | 73 | 190 | 132 | 127 | 100 |

| 3 | 88.9 | 229 | 159 | 152 | 121 |

| 3.1/2 | 101.6 | 267 | 184 | 178 | 140 |

| 4 | 114.3 | 305 | 210 | 203 | 159 |

| 5 | 141.3 | 381 | 262 | 254 | 197 |

| 6 | 168.3 | 457 | 313 | 305 | 237 |

| 8 | 219.1 | 610 | 414 | 406 | 313 |

| 10 | 273 | 762 | 518 | 508 | 391 |

| 12 | 323.8 | 914 | 619 | 610 | 467 |

| 14 | 355.6 | 1067 | 711 | 711 | 533 |

| 16 | 406.4 | 1219 | 813 | 813 | 610 |

| 18 | 457 | 1372 | 914 | 914 | 686 |

| 20 | 508 | 1524 | 1016 | 1016 | 762 |

| 22 | 559 | 1676 | 1118 | 1118 | 838 |

| 24 | 610 | 1829 | 1219 | 1219 | 914 |

High Nickel Alloy Elbow Tolerance

| Buttweld Fittings ASME B16.9 Elbow Tolerance | 45 Deg. Elbow |

90 Deg. Elbow |

|||

|---|---|---|---|---|---|

| Buttweld Fitting Dimension (NPS) | Outside Diameter at Bevel |

Inside Diameter at End |

WallThickness T | Center-to-End Dimension A ,C ,B |

Center-to-End Dimension A ,C ,B |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.06 | +/- 0.06 | |

| -0.03 | |||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | |

| 10 to 18 | +0.16 | +/- 0.12 | +/- 0.09 | +/- 0.09 | |

| -0.12 | |||||

| 20 to 24 | +0.25 | +/- 0.19 | +/- 0.09 | +/- 0.09 | |

| -0.19 | |||||

| 26 to 30 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.12 | |

| -0.19 | |||||

| 32 to 48 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.19 | |

| -0.19 | |||||

ASTM B366 Elbow Applications

Oil and Gas

Nuclear Power & Defence

Petrochemical

LNG

Desalination

Mining & Minerals

Myanmar, Nepal, Thailand, Vietnam, Philippines, Malaysia, Indonesia,

Singapore, Taiwan, Tasmania, Sri Lanka, Bangladesh, Bhutan, Cambodia,

Australia, New Zealand, Afghanistan, Tajikistan, Kyrgyzstan, Kazakhstan,

Uzbekistan, Turkmenistan, Iran, United Arab Emirates(UAE), Saudi Arabia,

Oman, Yemen, Iraq, Azerbaijan, Turkiye, Syria, Lebanon, Israel, Kenya,

Egypt, South Sudan, Eritrea, Djibouti, Ethiopia, Libya, Rwanda, Mali,

Niger, Chad, Central Africa Republic, Nigeria, Cameroon, Somalia, DRC,

Uganda, Tanzania, Angola, Zambia, Madagascar, Malawi, Namibia, Benin,

Zimbabwe, Botswana, Lesotho, South Africa, Algeria, Tunisia, Morocco,

Eswatini, Liberia, Sierra Leone, The Gambia, Senegal, Mozambique, Togo,

Mauritania, Burkina Faso, Ghana, Equatorial Guinea, Jordan, Timor-Leste,

Palestine, Laos, Armenia, Georgia, Maldives, Cyprus, Kuwait, Qatar, Peru,

Bahrain, Brunei, Finland, France, Germany, Ireland, Iceland, UK, US,

Greece, Hungary, Italy, Norway, Poland, Slovakia, Sweden, Canada, Fiji,

Romania, Cuba, Panama, Brazil, Colombia, Chile, Argentina, Venezuela,

Naypyidaw, Kathmandu, Bangkok, Hanoi, Manila, Kuala Lumpur, Jakarta, Tunis,

Jurong East, Taipei City, Hobart, Sri Jayawardenepura Kotte, Dhaka, Thimphu,

Phnom Penh, Canberra, Wellington, Kabul, Dushanbe, Bishkek, Astana, Abuja,

Tashkent, Ashgabat, Tehran, Abu Dhabi, Riyadh, Muscat, Sana’a, Baghdad, Pretoria,

Baku, Ankara, Damascus, Beirut, Jerusalem, Nairobi, Cairo, Juba, Asmara, Rabat,

Djibouti city, Addis Ababa, Tripoli, Kigali, Bamako, Niamey, N’Djamena, Bangui,

Yaoundé, Mogadishu, Kinshasa, Kampala, Dodoma, Luanda, Lusaka, Antananarivo,

Lilongwe, Windhoek, Porto-Novo, Harare, Gaborone, Maseru, Cape Town, Bloemfontein,

Algiers, Mbabane, Lobamba, Monrovia, Freetown, Banjul, Dakar, Maputo, Lomé, Dili,

Nouakchott, Ouagadougou, Accra, Malabo, Amman, Vientiane, Yerevan, Tbilisi, Rome,

Malé, Nicosia, Kuwait City, Doha, Lima, Manama, Bandar Seri Begawan, Paris,

Helsinki, Berlin, Dublin, Reykjavík, London, Washington D.C., Athens, Budapest,

Oslo, Warsaw, Bratislava, Stockholm, Ottawa, Suva, Bucharest, Havana, Panama City,

Brasília, Bogotá, Santiago, Buenos Aires, Caracas, Mumabi, Chennai, Bengaluru,

Kolkata, Hyderabad, Pune, Ahmedabad, Jaipur, Surat, Visakhapatnam, Indore, New Delhi

Lucknow, Nagpur, Kochi, Kanpur, Guwahati, Coimbatore, Noida, Ghaziabad, Patna