ASME B16.11 Sockolet Fitting Manufacturers and Suppliers:

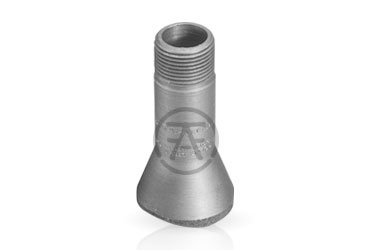

A Sockolet is a type of forged fitting that is used to connect a smaller branch pipe to a larger pipe or vessel. It is designed with a socket or bore to accommodate the pipe’s outside diameter, and a weld or fillet on the outer surface that connects the fitting to the larger pipe or vessel.

Dimensions for Sockolets vary depending on the size of the branch pipe and the larger pipe or vessel to which it is being connected. A size chart is typically used to determine the appropriate dimensions, which may include the outside diameter, bore diameter, overall length, and wall thickness of the fitting.

ISO Approved ASME/ANSI B16.11 Sockolet Manufacturer In India, ASME B31.3 Sockolet Fittings, MSS SP-97 Sockolet Dimensions Chart, Tolerances, Weight Chart, Thickness Chart, Cad Drawing

The run size of a Sockolet refers to the size of the branch pipe that is being connected. This can range from small diameters up to larger sizes, depending on the application.

ASME B16.11 is a standard that covers the requirements for forged fittings, including Sockolets. It specifies the dimensions, tolerances, materials, and testing requirements for these fittings.

Sockolets can be used in a wide range of applications, including oil and gas, petrochemical, chemical, and power generation industries. They are typically made from high-quality materials such as ASTM A182, which is a standard specification for forged or rolled alloy and stainless steel pipe flanges, fittings, valves, and parts.

Sockolets are available in a range of classes, including class 3000, class 6000, and class 9000. These classes refer to the pressure rating of the fitting and determine its suitability for use in various applications.

Carbon steel is a commonly used material for Sockolets due to its high strength, durability, and resistance to corrosion. As a manufacturer of Sockolets, ADCO Forge and Fittings offers a range of high-quality fittings that are designed to meet the needs of a variety of industries and applications.

We have the ready inventory of Sockolet Fitting in the different size ranges of 1 Inch, 1 1/2 Emt, 1/2 Npt, 2 Inch, 2 x 1 Npt, 3/4 Npt, 3 Inch, 4 Inch, 4 x 3/4 Emt, 5 Inch, 6 Inch, 7 Inch, 7/8 Npt, 8 Inch, 9 Inch.

Sockolet Fitting Standard Specifications

Standards

ASME B31.3, B31.1, B31.8, B31.4, ASME/ANSI B16.11, MSS-SP-97

Thickness

SCH 5S, SCH 10S, SCH 40S, SCH 80S, SCH 120S

Type

Bevelled and Socket type

Dimensions

ASME B31.3,1,8,4 | ASME/ANSI B16.11 | MSS-SP-97 | JIS B2316 | BS 3799

Size Range (inches)

From 2″ – 24″

Class

6000LBS, 3000LBS, 9000LBS

Schedule 40 & Schedule 80 Sockolet in Stainless Steel 304/304L, SS 316/316L, SS 904L, Alloy 20, Carbon A234 WPB, Nickel 200, Monel, Inconel, Hastelloy C22, Duplex Steel 2205, Titanium, Copper Nickel, SMO 254, Aluminum, Brass, Cast Iron, Galvanized, MS Sockolet. Get best Price List.

ASME B16.11 Outlet Fittings Types

If you are looking for ASME B16.11 Olets Fittings types, weight chart, size chart, tolerance, and dimensions with drawings then kindly click the below-mentioned forms of pipe fittings as per your requirements to get the complete details. For the quick quote / price list click here.

ASME B16.11 Sockolet Material Grades

| Stainless Steel Sockolet: | ASTM A182/SA182 WP Gr. 304, 304L, 304H, 310, 310S, 316, 316L, 316H, 316Ti, 317, 317L, 321, 321H, 347, 347H, 446, 904L |

|---|---|

| Carbon Steel Sockolet: | ASTM A105/SA105, ASTM A694/SA694, Gr. F42/46/52/56/60/65/70 |

| Low Temperature Carbon Steel Sockolet | ASTM A350 LF3/A350 LF2 |

| Alloy Steel Sockolet: | ASTM A182/SA182 F1/F5/F9/F11/F22/F91 |

| Duplex & Super Duplex Sockolet: | ASTM A182, ASME SA182 F 44, F 45, F51, F 53, F 55, F 60, F 61. |

| Nickel Alloy Sockolet: | ASTM / ASME SB 564 / 160 / 472 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UND 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C276 ), Cupro Nickel 90/10 ( C70600, 2.0872 ), 70/30 ( C71500, 2.0882) |

| Other Steel Sockolet: | ASTM B363 Titanium Grade 2 ( R50400, 3.7035 ), Titanium Grade 2 ( N56400, 3.7165 ), ASTM A403 SMO 254/AL-6XN ( S31254, 1.4547 ), AISI 4130 ( G41300, 1.7218 ) |

ASME B16.11 Sockolet Dimensions & Weight Chart

ASME B16.11 Sockolet Fitting - Dimensions & Weight Chart

Dimensions of Sockolet MSS SP-97 (Class 3000 “Size on Size”)

| Outlet Size (NPT) | A | B | C | D | E | Approx. Weight (lb) |

|---|---|---|---|---|---|---|

| 1/2 | 1 | 1 3/8 | 15/16 | 0.622 | 17/32 | 0.15 |

| 3/4 | 1 1/16 | 1 5/8 | 1 3/16 | 0.824 | 15/32 | 0.25 |

| 1 | 1 5/16 | 2 | 1 7/16 | 1.049 | 23/32 | 0.45 |

| 1 1/4 | 1 5/16 | 2 3/8 | 1 3/4 | 1.380 | 9/16 0.65 | |

| 1 1/2 | 1 3/8 | 2 7/8 | 2 | 1.610 | 21/32 | 0.85 |

| 2 | 1 1/2 | 3 1/2 | 2 9/16 | 2.067 | 15/16 | 1.40 |

| 2 1/2 | 1 9/16 | 4 1/16 | 3 | 2.469 | 3/4 | 2.25 |

| 3 | 1 3/4 | 4 13/16 | 3 11/16 | 3.068 | 15/16 | 3.75 |

| 3 1/2 | 1 11/16 | 5 3/8 | 4 7/16 | 3.548 | 11/16 | 4.30 |

| 4 | 1 7/8 | 6 1/16 | 4 3/4 | 4.026 | 1 1/16 | 6.60 |

| 5 | 2 7/16 | 7 1/4 | 5 1/4 | 5.047 | 1 | 9.00 |

| 6 | 2 11/16 | 8 11/16 | 6 1/16 | 6.065 | 1 3/16 | 15.50 |

Dimensions of Sockolet MSS SP-97 (Class 6000 “Size on Size”)

| Outlet Size (NPS) | A | B | C | D | E | Approx. Weight (lb) |

|---|---|---|---|---|---|---|

| 1/2 | 1 1/4 | 1 23/32 | 3/4 | 0.466 | 7/8 | 0.50 |

| 3/4 | 1 7/16 | 1 61/64 | 1 | 0.614 | 7/8 | 0.80 |

| 1 | 1 9/16 | 2 7/16 | 1 5/16 | 0.815 | 15/16 | 1.30 |

| 1 1/4 | 1 5/8 | 2 23/32 | 1 1/2 | 1.160 | 13/16 | 1.60 |

| 1 1/2 | 1 11/16 | 3 1/4 | 1 15/16 | 1.338 | 7/8 | 2.00 |

| 2 | 2 1/16 | 4 1/32 | 2 3/4 | 1.689 | 1 3/16 | 5.15 |

Q: What is a sockolet?

A: A sockolet is a type of branch connection fitting used in piping systems. It is designed to provide a convenient and reliable way to create a branch connection on a main pipeline. The sockolet has a socket-like configuration, with a round opening that allows for the insertion of a pipe or tube for creating the branch.

Q: What is the purpose of a sockolet?

A: The primary purpose of a sockolet is to facilitate branching from a main pipeline without the need for complex and time-consuming welding procedures. It provides a strong and leak-proof connection between the branch and the main pipe, making it suitable for high-pressure and high-temperature applications.

Q: How does a sockolet work?

A: A sockolet is welded onto the main pipe at the desired location for the branch connection. The round opening of the sockolet serves as a socket where the end of the branch pipe is inserted and welded. This creates a secure and reliable connection, eliminating the need for additional components or complex welding techniques.

Q: What materials are sockolets made of?

A: Sockolets are available in various materials to suit different applications and requirements. Common materials include carbon steel, stainless steel, alloy steel, and other corrosion-resistant alloys. The material selection depends on factors such as the nature of the fluid being transported, temperature, pressure, and environmental conditions.

Q: What is the difference between a weldolet and a sockolet?

A: The main difference between a weldolet and a sockolet lies in their connection methods. While both fittings are used for creating branch connections, a weldolet is designed to be welded directly onto the main pipe, requiring a beveled end and welding process. On the other hand, a sockolet is socket-welded onto the main pipe, allowing for easier and quicker installation without the need for beveling or complex welding.

Q: When should I use a sockolet or a weldolet?

A: The choice between a sockolet and a weldolet depends on the specific requirements of the piping system. A sockolet is generally preferred when quick and simple installation is desired, especially for smaller branch connections and applications with moderate pressure and temperature requirements. Weldolets are typically used for larger branch connections or in cases where welding is preferred or specified.

Q: Are sockolets and weldolets interchangeable?

A: Sockolets and weldolets are not interchangeable as they have different installation methods and requirements. The decision between the two should be based on the design specifications, application needs, and compatibility with the main pipe material. It is essential to consult with piping experts or engineers to determine the most suitable branch connection fitting for your specific project.

MSS SP-97 Sockolet Applications

Oil and Gas

Nuclear Power & Defence

Petrochemical

LNG

Desalination

Mining & Minerals

Myanmar, Nepal, Thailand, Vietnam, Philippines, Malaysia, Indonesia,

Singapore, Taiwan, Tasmania, Sri Lanka, Bangladesh, Bhutan, Cambodia,

Australia, New Zealand, Afghanistan, Tajikistan, Kyrgyzstan, Kazakhstan,

Uzbekistan, Turkmenistan, Iran, United Arab Emirates(UAE), Saudi Arabia,

Oman, Yemen, Iraq, Azerbaijan, Turkiye, Syria, Lebanon, Israel, Kenya,

Egypt, South Sudan, Eritrea, Djibouti, Ethiopia, Libya, Rwanda, Mali,

Niger, Chad, Central Africa Republic, Nigeria, Cameroon, Somalia, DRC,

Uganda, Tanzania, Angola, Zambia, Madagascar, Malawi, Namibia, Benin,

Zimbabwe, Botswana, Lesotho, South Africa, Algeria, Tunisia, Morocco,

Eswatini, Liberia, Sierra Leone, The Gambia, Senegal, Mozambique, Togo,

Mauritania, Burkina Faso, Ghana, Equatorial Guinea, Jordan, Timor-Leste,

Palestine, Laos, Armenia, Georgia, Maldives, Cyprus, Kuwait, Qatar, Peru,

Bahrain, Brunei, Finland, France, Germany, Ireland, Iceland, UK, US,

Greece, Hungary, Italy, Norway, Poland, Slovakia, Sweden, Canada, Fiji,

Romania, Cuba, Panama, Brazil, Colombia, Chile, Argentina, Venezuela,

Naypyidaw, Kathmandu, Bangkok, Hanoi, Manila, Kuala Lumpur, Jakarta, Tunis,

Jurong East, Taipei City, Hobart, Sri Jayawardenepura Kotte, Dhaka, Thimphu,

Phnom Penh, Canberra, Wellington, Kabul, Dushanbe, Bishkek, Astana, Abuja,

Tashkent, Ashgabat, Tehran, Abu Dhabi, Riyadh, Muscat, Sana’a, Baghdad, Pretoria,

Baku, Ankara, Damascus, Beirut, Jerusalem, Nairobi, Cairo, Juba, Asmara, Rabat,

Djibouti city, Addis Ababa, Tripoli, Kigali, Bamako, Niamey, N’Djamena, Bangui,

Yaoundé, Mogadishu, Kinshasa, Kampala, Dodoma, Luanda, Lusaka, Antananarivo,

Lilongwe, Windhoek, Porto-Novo, Harare, Gaborone, Maseru, Cape Town, Bloemfontein,

Algiers, Mbabane, Lobamba, Monrovia, Freetown, Banjul, Dakar, Maputo, Lomé, Dili,

Nouakchott, Ouagadougou, Accra, Malabo, Amman, Vientiane, Yerevan, Tbilisi, Rome,

Malé, Nicosia, Kuwait City, Doha, Lima, Manama, Bandar Seri Begawan, Paris,

Helsinki, Berlin, Dublin, Reykjavík, London, Washington D.C., Athens, Budapest,

Oslo, Warsaw, Bratislava, Stockholm, Ottawa, Suva, Bucharest, Havana, Panama City,

Brasília, Bogotá, Santiago, Buenos Aires, Caracas, Mumabi, Chennai, Bengaluru,

Kolkata, Hyderabad, Pune, Ahmedabad, Jaipur, Surat, Visakhapatnam, Indore, New Delhi

Lucknow, Nagpur, Kochi, Kanpur, Guwahati, Coimbatore, Noida, Ghaziabad, Patna