ASME B16.11 Weldolet Fitting Manufacturers and Suppliers:

A Weldolet is a type of pipe fitting used for branch connections on pipes. It is designed to fit over the run pipe and be welded onto it, with a branch pipe connected to the other end. This creates a strong and permanent connection between the pipes, making it an efficient and durable solution for piping systems.

Weldolets come in various dimensions and sizes to fit different pipe systems. The dimensions of a Weldolet depend on the diameter and thickness of the run and branch pipes. The sizes range from 1/2 inch to 36 inches, with a maximum wall thickness of 3 inches.

ISO Approved ASME/ANSI B16.11 Weldolet Manufacturer In India, ASME B31.3 Weldolet Fittings, MSS SP-97 Weldolet Dimensions Chart, Tolerances, Weight Chart, Thickness Chart, Cad Drawing

ASME B16.25 is a standard specification for butt-welded fittings, including Weldolets. This specification covers the dimensions and tolerances of Weldolets, as well as their marking and material requirements.

ASTM A105 is a standard specification for carbon steel forgings for piping applications. Weldolets made from ASTM A105 material are designed to withstand high-temperature and high-pressure environments, making them suitable for use in a variety of industries.

A234 is a standard specification for piping fittings made from wrought carbon steel and alloy steel materials. A234 Weldolets are designed to meet the requirements of ASME B16.9 and ASME B16.25 standards and are available in various sizes and dimensions to fit different pipe systems.

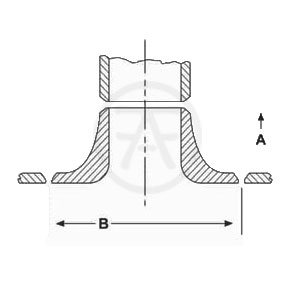

An Inserted Weldolet is a type of branch connection fitting that is welded onto the run pipe with the use of a set-in pipe. The set-in pipe is inserted into the run pipe and welded in place, creating a reinforcing pad for the Weldolet. The Weldolet is then welded onto the set-in pipe, providing a branch connection for the secondary pipe.

Inserted Weldolets are often used in high-pressure and high-temperature piping systems where a strong and reliable connection is required. They are available in a range of materials, including carbon steel, stainless steel, and nickel alloys, and can be customized to fit specific pipe systems. Like other types of Weldolets, inserted Weldolets are designed to provide a leak-free and permanent connection between the run pipe and branch pipe.

We have the ready inventory of Weldolet Fitting in the different size ranges of 4 Inch, 1/2 Npt, 1/4 Npt, 1 Inch, 1 1/2 Emt, 2 Inch, 2-1/2 Emt, 3 Inch, 3/4 Npt, 4 Inch, 5 Inch, 6 Inch, 8 Inch, 8 x 2 Emt, 12 Inch Weldolets.

Weldolet Fitting Standard Specifications

Standards

ASME B31.3, B31.1, B31.8, B31.4, ASME/ANSI B16.11, MSS-SP-97

Thickness

SCH 5S, SCH 10S, SCH 40S, SCH 80S, SCH 120S

Type

Bevelled and Welded

Dimensions

ASME B31.3,1,8,4 | ASME/ANSI B16.11 | MSS-SP-97 | JIS B2316 | BS 3799

Size Range (inches)

From 2″ – 24″

Class

6000LBS, 3000LBS, 9000LBS

Schedule 40 & Schedule 80 Weldolet in Stainless Steel 304/304L, SS 316/316L, SS 904L, Alloy 20, Carbon A234 WPB, Nickel 200, Monel, Inconel, Hastelloy C22, Duplex Steel 2205, Titanium, Copper Nickel, SMO 254, Aluminum, Brass, Cast Iron, Galvanized, MS Weldolet. Get best Price List.

ASME B16.11 Outlet Fittings Types

If you are looking for ASME B16.11 Olets Fittings types, weight chart, size chart, tolerance, and dimensions with drawings then kindly click the below-mentioned forms of pipe fittings as per your requirements to get the complete details. For the quick quote / price list click here.

ASME B16.11 Weldolet Material Grades

| Stainless Steel Weldolet: | ASTM A182/SA182 WP Gr. 304, 304L, 304H, 310, 310S, 316, 316L, 316H, 316Ti, 317, 317L, 321, 321H, 347, 347H, 446, 904L |

|---|---|

| Carbon Steel Weldolet: | ASTM A105/SA105, ASTM A694/SA694, Gr. F42/46/52/56/60/65/70 |

| Low Temperature Carbon Steel Weldolet | ASTM A350 LF3/A350 LF2 |

| Alloy Steel Weldolet: | ASTM A182/SA182 F1/F5/F9/F11/F22/F91 |

| Duplex & Super Duplex Weldolet: | ASTM A182, ASME SA182 F 44, F 45, F51, F 53, F 55, F 60, F 61. |

| Nickel Alloy Weldolet: | ASTM / ASME SB 564 / 160 / 472 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UND 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C276 ), Cupro Nickel 90/10 ( C70600, 2.0872 ), 70/30 ( C71500, 2.0882) |

| Other Steel Weldolet: | ASTM B363 Titanium Grade 2 ( R50400, 3.7035 ), Titanium Grade 2 ( N56400, 3.7165 ), ASTM A403 SMO 254/AL-6XN ( S31254, 1.4547 ), AISI 4130 ( G41300, 1.7218 ) |

The flexible branch of a Flexolet allows for slight movement, accommodating thermal expansion and contraction in the pipeline.

Sockolets are known for their ease of installation and are suitable for smaller pipe sizes and lower-pressure applications.

Latrolets are used in situations where a 45-degree branch is required, such as in certain piping layouts and configurations.

A Brazolet is a branch connection fitting used to create a branch connection with a socket-welded or threaded outlet. It is often used in smaller pipe sizes and lower-pressure applications.

A Coupolet is a branch connection fitting that allows for a full-size branch connection from the main pipeline.

A Flangolet is a branch connection fitting designed with a flanged outlet. It allows for the connection of a flanged component, such as a valve or flange, to the main pipeline.

A Flexolet is a branch connection fitting with a flexible branch outlet. It is used in applications where thermal expansion or vibration may occur.

A Latrolet is a type of branch connection fitting designed to create a 45-degree branch connection from a main pipeline.

A Nipolet is a combination of a Weldolet and a concentric reducer. It is used to create a branch connection with a smaller diameter than the main pipeline.

A Sockolet is a branch connection fitting that resembles a socket-welded tee. It is welded onto the main pipe to create a branch outlet.

A Sweepolet is a branch connection fitting with a curved, sweeping outlet. It is used to create a gradual, sweeping branch connection.

A Thredolet is a branch connection fitting that has female threads on one end and is welded onto the main pipe. It allows for the installation of threaded branch connections.

A Weldolet is a type of branch connection fitting used to create a branch from a main pipeline by welding it onto the pipe. It resembles a welding elbow with a branch outlet.

An Elbolet is a branch connection fitting designed to create a 90-degree branch from a main pipeline, similar to a welding elbow with an outlet.

Brazolets are commonly used in situations where socket-welded or threaded connections are more suitable, such as in plumbing and smaller industrial applications.

Elbolets are used when a 90-degree branch connection is required and space constraints prevent the use of larger fittings.

Coupolets are often used in applications where a full-sized branch is needed to maintain flow capacity.

Flangolets are used when a flanged connection is required for the branch outlet, often in situations where frequent disassembly is necessary.

Nipolets are often used in applications where a reduction in pipe size is necessary for the branch connection.

Sweepolets are employed in piping systems where a smooth, low-turbulence flow is desired, such as in the food and pharmaceutical industries.

Thredolets are often used when you need to create threaded branch connections in pipelines, such as in plumbing and industrial applications.

Weldolets are often used in high-pressure and high-temperature applications, such as in the oil and gas industry, where a branch connection is needed.

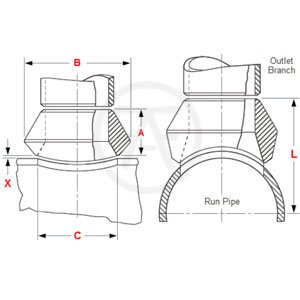

ASME B16.11 Weldolet Dimensions

ASME B16.11 Weldolet - Dimensions Chart

Dimensions of Weldolet (NPS 1/2 - 24 STD Size on Size)

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1.1/4 | 1.1/4 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1.1/2 | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1.1/2 38.10 |

3.1/2 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2.1/2 | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3.1/2 | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2.1/4 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8.1/2 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3.1/2 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13.1/4 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23.1/4 590.55 |

Dimensions of Weldolet (NPS 1/2 - 24 XS Size on Size)

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1.1/4 | 1.1/4 31.75 |

2.7/16 61.91 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1.1/2 | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1.1/2 38.10 |

3.1/2 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2.1/2 | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3.1/2 | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2.1/4 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 3.1/16 77.79 |

8.7/8 225.43 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 3.7/8 98.43 |

10.5/8 269.88 |

8.11/16 220.66 |

7.5/8 193.68 |

| 10 | 3.1/2 88.90 |

12.7/8 327.03 |

10.7/16 265.11 |

9.3/4 254.00 |

| 12 | 3.15/16 100.01 |

15.3/16 385.76 |

13 330.20 |

11.3/4 304.80 |

| 14 | 4.1/8 104.78 |

16.11/16 423.86 |

14.5/16 363.54 |

13 330.20 |

| 16 | 4.7/16 112.71 |

18.7/8 479.43 |

16.1/2 419.10 |

15 381.00 |

| 18 | 4.11/16 119.06 |

21.1/8 536.58 |

18.5/8 473.08 |

17 431.80 |

| 20 | 5 127.00 |

23.3/8 593.73 |

20.13/16 528.64 |

19 482.60 |

| 24 | 5.1/2 139.70 |

27.7/8 708.03 |

25.1/8 638.18 |

23 584.20 |

Dimensions of Weldolet (NPS 3/4 - 20 STD Reducing)

| NPS | A | B | C |

|---|---|---|---|

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

| 3/4 | 7/8 22.23 |

1.3/4 44.45 |

1.3/16 30.16 |

| 1 | 1.1/16 26.99 |

2.1/8 53.98 |

1.7/16 36.51 |

| 1.1/4 | 1.1/4 31.75 |

2.9/16 65.09 |

1.3/4 44.45 |

| 1.1/2 | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

| 2 | 1.1/2 38.10 |

3.1/2 88.90 |

2.9/16 65.09 |

| 2.1/2 | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

| 3.1/2 | 1.7/8 47.63 |

5.5/8 142.88 |

4 101.60 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

| 5 | 2.1/4 57.15 |

7.1/16 179.39 |

5.9/16 141.29 |

| 6 | 2.3/8 60.3 |

8.1/2 215.90 |

6.11/16 169.86 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

| 10 | 3.1/16 77.79 |

12.11/16 322.26 |

10.13/16 274.64 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

| 14 | 3.1/2 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

| 18 | 3.13/16 96.84 |

20.1/2 520.70 |

18.1/16 458.79 |

| 20 | 4 101.60 |

22.1/2 571.50 |

20 508.00 |

| 24 | 4.9/16 115.89 |

27.1/8 688.98 |

24.3/16 614.36 |

Dimensions of Weldolet (NPS 3/4 - 20 XS Reducing)

| NPS | A | B | C |

|---|---|---|---|

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

| 3/4 | 7/8 22.23 |

1.3/4 44.45 |

1.3/16 30.16 |

| 1 | 1.1/16 26.99 |

2.1/8 53.98 |

1.7/16 36.51 |

| 1.1/4 | 1.1/4 31.75 |

2.9/16 65.09 |

1.3/4 44.45 |

| 1.1/2 | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

| 2 | 1.1/2 38.10 |

3.1/2 88.90 |

2.9/16 65.09 |

| 2.1/2 | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

| 3.1/2 | 1.7/8 47.63 |

5.5/8 142.88 |

4 101.60 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

| 5 | 2.1/4 57.15 |

7.1/16 179.39 |

5.9/16 141.29 |

| 6 | 2.3/8 60.3 |

8.1/2 215.90 |

6.11/16 169.86 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

| 10 | 3.1/16 77.79 |

12.11/16 322.26 |

10.13/16 274.64 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

| 14 | 3.1/2 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

| 18 | 3.13/16 96.84 |

20.1/2 520.70 |

18.1/16 458.79 |

| 20 | 4 101.60 |

22.1/2 571.50 |

20 508.00 |

| 24 | 4.9/16 115.89 |

27.1/8 688.98 |

24.3/16 614.36 |

Dimensions of Insert Weldolet

| Normal Size Of Outlet |

(Height above run pipe) Dimensions Of A' | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2 | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |

| Std Wt Run Pipe | 1.50 | 1.50 | 1.62 | 1.75 | 2.00 | 2.25 | 2.38 | 2.75 | 3.06 | 3.38 | 3.50 | 3.75 | 3.81 | 4 | 4.56 |

| XS Run Pipe | 1.50 | 1.50 | 1.62 | 1.75 | 2.00 | 2.25 | 3.06 | 3.87 | 3.69 | 4.06 | 3.81 | 4.19 | 4.38 | 4.69 | 5.50 |

| .500" to .750" Thickness Run Pipe | - | - | - | 2.88 | 3.31 | 3.75 | 4.12 | 4.18 | 4.25 | 4.37 | 4.50 | 4.69 | 5.13 | 5.62 | 6.50 |

| .750" to 1.00" Thickness Run Pipe | - | - | - | 3.22 | 3.38 | 3.75 | 4.34 | 4.62 | 4.84 | 5.10 | 5.25 | 5.88 | 6.50 | 6.75 | 7.62 |

| 1.00" to 1.25" Thickness Run Pipe | - | - | - | 3.38 | 3.50 | 4.00 | 4.50 | 4.88 | 5.00 | 5.38 | 5.50 | 6.00 | 6.50 | 7.00 | 8.00 |

| 1.25" to 1.50" Thickness Run Pipe | - | - | - | 3.62 | 3.87 | 4.25 | 4.69 | 5.16 | 5.31 | 5.68 | 5.81 | 6.44 | 6.50 | 7.56 | 8.72 |

ASME B16.11 Weldolet Weight Chart

| Size Of Weldolet In inches | (A) | (B) | (C) | (D) | Weight in LBS |

|---|---|---|---|---|---|

| 1/2 | 3/4 | 1 3/8 | 15/16 | 5/8 | 0.15 |

| 3/4 | 7/8 | 1 5/8 | 1 3/16 | 13/16 | 0.25 |

| 1 | 1 1/16 | 2 | 1 7/16 | 1 1/32 | 0.4 |

| 1 1/4 | 1 1/4 | 2 3/8 | 1 3/4 | 1 3/8 | 0.7 |

| 1 1/2 | 1 5/16 | 2 7/8 | 2 | 1 5/8 | 0.8 |

| 2 | 1 1/2 | 3 1/2 | 2 9/16 | 2 1/16 | 1.5 |

| 2 1/2 | 1 5/8 | 4 1/6 | 3 | 2 7/16 | 2.25 |

| 3 | 1 3/4 | 4 13/16 | 3 11/16 | 3 1/16 | 3.75 |

| 3 1/2 | 2 | 5 3/8 | 3 7/8 | 3 9/16 | 5 |

| 4 | 2 | 6 | 4 3/4 | 4 | 6.7 |

| 5 | 2 1/4 | 7 1/8 | 5 9/16 | 5 1/16 | 8.5 |

| 6 | 2 3/8 | 8 1/2 | 6 11/16 | 6 1/16 | 14 |

| 8 | 2 3/4 | 10 3/8 | 8 11/16 | 7 15/16 | 28 |

| 10 | 3 1/16 | 12 9/16 | 10 13/16 | 10 | 39 |

| 12 | 3 3/8 | 14 7/8 | 12 13/16 | 12 | 65 |

| 14 | 3 1/2 | 16 1/8 | 14 1/16 | 13 1/4 | 70 |

| 16 | 3 11/16 | 18 1/4 | 16 1/16 | 15 1/4 | 92 |

| 18 | 4 1/16 | 20 3/4 | 18 5/8 | 17 1/4 | 125 |

| 20 | 4 5/8 | 23 1/16 | 20 1/16 | 19 1/4 | 175 |

| 24 | 5 3/8 | 27 7/8 | 25 1/8 | 23 1/4 | 280 |

| 30 | 5 3/8 | 34 1/16 | 30 7/16 | 29 1/4 | 440 |

| 36 | 5 3/8 | 34 1/16 | 36 1/2 | 35 1/4 | 1180 |

Q: What is a weldolet used for?

A: A weldolet is a type of pipe fitting that is used to create branch connections in piping systems. It is specifically designed to provide a smooth and efficient transition from the main pipe run to a smaller diameter branch pipe. Weldolets are commonly used in applications where the branch connection needs to be welded to the main pipe, such as in high-pressure and high-temperature pipelines.

Q: What type of welding is weldolet?

A: Weldolets are typically used in conjunction with butt welding, which is a type of arc welding technique. Butt welding involves joining two pieces of metal by heating the ends to their melting point and then allowing them to fuse together. Weldolets have a beveled end that is welded directly to the main pipe run using the butt welding method. This ensures a strong and leak-free connection between the weldolet and the main pipe.

Q: What is the specification of weldolet?

A: The specifications of weldolets can vary depending on the specific application and the standards followed by the manufacturer. However, some general specifications include the material of construction, size, pressure rating, and dimensions. Weldolets are available in various materials such as carbon steel, stainless steel, and alloy steel. They come in different sizes ranging from small diameters to larger ones to accommodate different branch pipe sizes. The pressure rating indicates the maximum pressure the weldolet can withstand. Dimensions include the length, width, and height of the weldolet, which are important for proper fitting and installation.

Q: What is the difference between weldolet and half coupling?

A: Weldolet and half coupling are both types of pipe fittings, but they serve different purposes. The main difference lies in their design and function.

- Weldolet: A weldolet is used to create a branch connection in a pipe run. It has a beveled end that is welded directly to the main pipe, providing a smooth transition for the branch pipe. Weldolets are typically used in applications where a permanent and strong welded connection is required.

- Half Coupling: A half coupling, on the other hand, is used to join two pipes of the same diameter. It has female threads on one end and a plain (unthreaded) end on the other. The threaded end of the half coupling is connected to a male threaded pipe, while the plain end is welded to the other pipe. Half couplings are commonly used in applications where the connection needs to be removable or where threaded connections are preferred.

MSS SP-97 Weldolet Applications

Oil and Gas

Nuclear Power & Defence

Petrochemical

LNG

Desalination

Mining & Minerals

Myanmar, Nepal, Thailand, Vietnam, Philippines, Malaysia, Indonesia,

Singapore, Taiwan, Tasmania, Sri Lanka, Bangladesh, Bhutan, Cambodia,

Australia, New Zealand, Afghanistan, Tajikistan, Kyrgyzstan, Kazakhstan,

Uzbekistan, Turkmenistan, Iran, United Arab Emirates(UAE), Saudi Arabia,

Oman, Yemen, Iraq, Azerbaijan, Turkiye, Syria, Lebanon, Israel, Kenya,

Egypt, South Sudan, Eritrea, Djibouti, Ethiopia, Libya, Rwanda, Mali,

Niger, Chad, Central Africa Republic, Nigeria, Cameroon, Somalia, DRC,

Uganda, Tanzania, Angola, Zambia, Madagascar, Malawi, Namibia, Benin,

Zimbabwe, Botswana, Lesotho, South Africa, Algeria, Tunisia, Morocco,

Eswatini, Liberia, Sierra Leone, The Gambia, Senegal, Mozambique, Togo,

Mauritania, Burkina Faso, Ghana, Equatorial Guinea, Jordan, Timor-Leste,

Palestine, Laos, Armenia, Georgia, Maldives, Cyprus, Kuwait, Qatar, Peru,

Bahrain, Brunei, Finland, France, Germany, Ireland, Iceland, UK, US,

Greece, Hungary, Italy, Norway, Poland, Slovakia, Sweden, Canada, Fiji,

Romania, Cuba, Panama, Brazil, Colombia, Chile, Argentina, Venezuela,

Naypyidaw, Kathmandu, Bangkok, Hanoi, Manila, Kuala Lumpur, Jakarta, Tunis,

Jurong East, Taipei City, Hobart, Sri Jayawardenepura Kotte, Dhaka, Thimphu,

Phnom Penh, Canberra, Wellington, Kabul, Dushanbe, Bishkek, Astana, Abuja,

Tashkent, Ashgabat, Tehran, Abu Dhabi, Riyadh, Muscat, Sana’a, Baghdad, Pretoria,

Baku, Ankara, Damascus, Beirut, Jerusalem, Nairobi, Cairo, Juba, Asmara, Rabat,

Djibouti city, Addis Ababa, Tripoli, Kigali, Bamako, Niamey, N’Djamena, Bangui,

Yaoundé, Mogadishu, Kinshasa, Kampala, Dodoma, Luanda, Lusaka, Antananarivo,

Lilongwe, Windhoek, Porto-Novo, Harare, Gaborone, Maseru, Cape Town, Bloemfontein,

Algiers, Mbabane, Lobamba, Monrovia, Freetown, Banjul, Dakar, Maputo, Lomé, Dili,

Nouakchott, Ouagadougou, Accra, Malabo, Amman, Vientiane, Yerevan, Tbilisi, Rome,

Malé, Nicosia, Kuwait City, Doha, Lima, Manama, Bandar Seri Begawan, Paris,

Helsinki, Berlin, Dublin, Reykjavík, London, Washington D.C., Athens, Budapest,

Oslo, Warsaw, Bratislava, Stockholm, Ottawa, Suva, Bucharest, Havana, Panama City,

Brasília, Bogotá, Santiago, Buenos Aires, Caracas, Mumabi, Chennai, Bengaluru,

Kolkata, Hyderabad, Pune, Ahmedabad, Jaipur, Surat, Visakhapatnam, Indore, New Delhi

Lucknow, Nagpur, Kochi, Kanpur, Guwahati, Coimbatore, Noida, Ghaziabad, Patna